5 Gallon Bottle Making Machine

5 gallon bottle making machine focus on 5 gallon bottle manufacturing.

What is 5 Gallon Bottle Making Machine?

5 gallon bottle making machine is a type of blow molding equipment specifically designed for the production of large-capacity PC and PET material for 5 gallon bottles. It is widely used in the manufacture of drinking water, purified water and mineral water bottles. As a standard large-capacity packaging container, 5 gallon bottle has become one of the standard containers in drinking water equipment. To meet the demands of large-scale, continuous and standardized production of 5 gallon bottle, 5 gallon bottle making machine emerged, becoming a significant supporting force for equipment upgrading and capacity expansion in this industry. According to different production processes, techniques of 5 gallon water bottle making machine can mainly be classified into several types such as injection blow molding, injection stretch blow molding and extrusion blow molding. Its core function is to process raw materials into preforms through steps such as heating, extrusion and injection molding. After that, it forms 5 gallon bottles that meet size requirements like uniform wall thickness and aesthetic appearance by using blow molding molds and high-pressure air.

5 gallon bottle making machine is not only suitable for industrial production lines of large-scale bottled water enterprises, but also for various types of factories such as small and medium-sized bottled water plants, pure water equipment factories and water dispenser accessory factories. In addition, it has significantly improved in terms of production efficiency, energy conservation and consumption reduction, becoming an important tool for enterprises to reduce costs and increase efficiency.

In the future, 5 gallon water bottle making machine will continue to play a key role in the major trends of green manufacturing and intelligent manufacturing, providing solid technical support for water bottle manufacturing.

In the future, 5 gallon water bottle making machine will continue to play a key role in the major trends of green manufacturing and intelligent manufacturing, providing solid technical support for water bottle manufacturing.

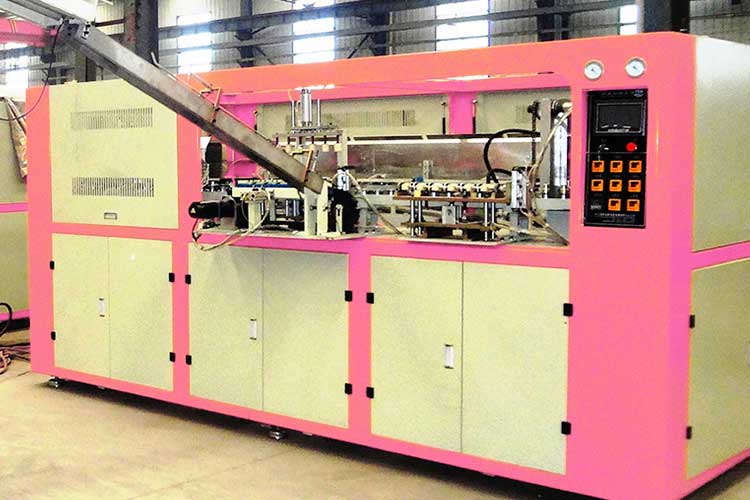

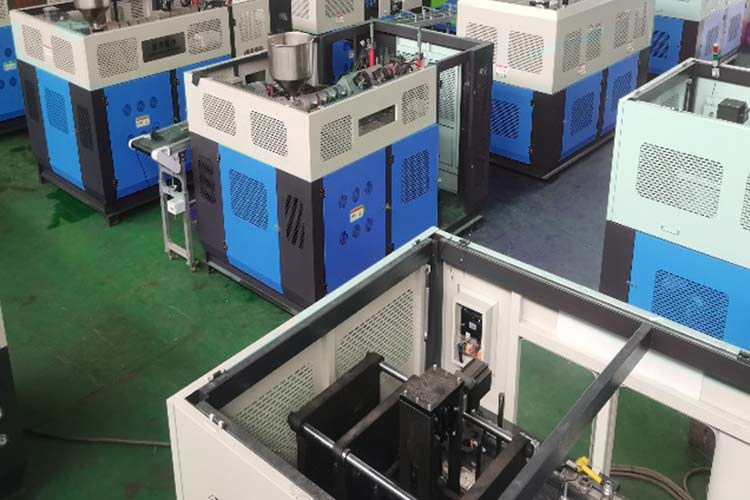

5 Gallon Bottle Making Machine Overview

5 Gallon Bottle Making Machine Installation Cases

Core Technologies of 5 Gallon Bottle Making Machine

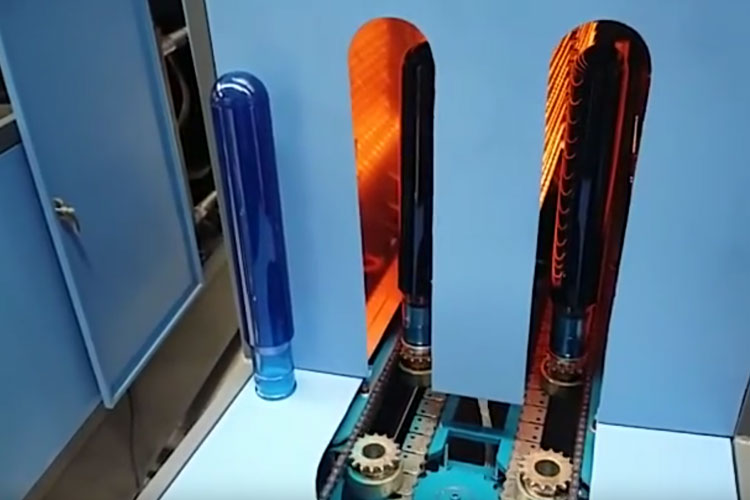

Stable and rapid preform feeding system

The continuous rotating turntable is adopted for preform feeding to achieve stable transmission of the preform from loading, preheating to mold positioning throughout the process, achieving the purpose of rapid and stable preform feeding.

The continuous rotating turntable is adopted for preform feeding to achieve stable transmission of the preform from loading, preheating to mold positioning throughout the process, achieving the purpose of rapid and stable preform feeding.

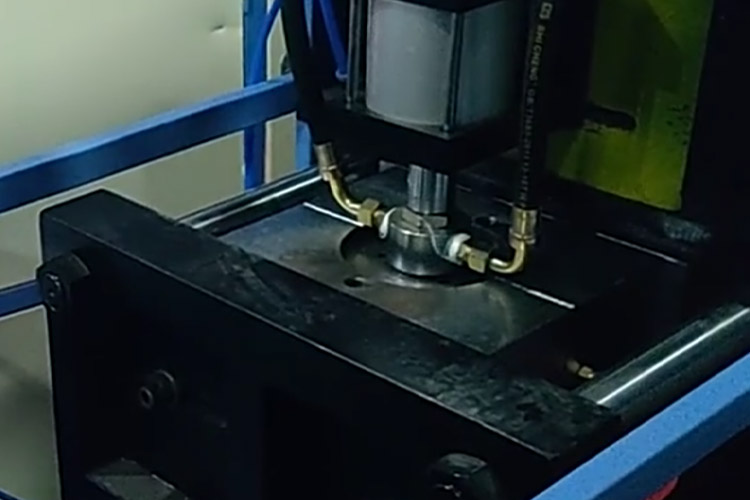

High-precision mold design

Modular design is adapted and combines with precise CNC processing technology. It is ensured to be durable and heat-resistant so that it is more convenient to be repaired and replaced in the later maintenance, effectively reducing maintenance costs.

Modular design is adapted and combines with precise CNC processing technology. It is ensured to be durable and heat-resistant so that it is more convenient to be repaired and replaced in the later maintenance, effectively reducing maintenance costs.

Fully automatic servo control system

By adopting a servo-driven electrode system, the actions of opening and closing the mold are integrated into one process, which shorten the bottle blowing cycle, increase the output and reach the level of full-line automation, improving the forming accuracy and production speed.

By adopting a servo-driven electrode system, the actions of opening and closing the mold are integrated into one process, which shorten the bottle blowing cycle, increase the output and reach the level of full-line automation, improving the forming accuracy and production speed.

Human-machine interface monitoring system

It is equipped with a touch-type color human-machine interface monitoring system, in which displays key parameters such as temperature, pressure and operating status in real time. Meanwhile, it has a fault diagnosis function, which is convenient for production management.

It is equipped with a touch-type color human-machine interface monitoring system, in which displays key parameters such as temperature, pressure and operating status in real time. Meanwhile, it has a fault diagnosis function, which is convenient for production management.

Intelligent heating control technology

Equipped with an infrared heating system and a multi-zone temperature control module, it can automatically adjust the heating power and time according to the material and thickness of the preform, achieving uniform preheating and saving 40% energy compared to traditional methods.

Equipped with an infrared heating system and a multi-zone temperature control module, it can automatically adjust the heating power and time according to the material and thickness of the preform, achieving uniform preheating and saving 40% energy compared to traditional methods.

High-pressure blowing system

A stable and reliable high-pressure blowing system is adopted to ensure that the bottle is rapidly inflated during the molding stage, making the bottle wall evenly distributed. Also, precise control of gas usage can reduce power consumption for low-pressure gases.

A stable and reliable high-pressure blowing system is adopted to ensure that the bottle is rapidly inflated during the molding stage, making the bottle wall evenly distributed. Also, precise control of gas usage can reduce power consumption for low-pressure gases.

Features of 5 Gallon Bottle Making Machine

Suitable for large-capacity container production

Provide high production efficiency and stable quality

Adopt energy-saving design and reduce cost Save labor with fully automatic production Ensure easy operation and convenient maintenance

Support multiple raw materials for production Support different preforms for production Provide safety protection mechanism

Adopt energy-saving design and reduce cost Save labor with fully automatic production Ensure easy operation and convenient maintenance

Support multiple raw materials for production Support different preforms for production Provide safety protection mechanism

5 Gallon Bottle Making Machine vs. Traditional Bottle Making Method

| Production Efficiency | High production efficiency | Low production efficiency |

|---|---|---|

| Product Consistency | Stable bottle shaping for high-quality requirement | Unstable and inconsistency product quality |

| Energy Consumption | Low energy consumption | High energy consumption |

| Production Automation | Fully automated production line | Manual-dependent operation |

| Working Space | Small working space for single machine | Large working space for different machines |

Raw Materials of 5 Gallon Bottle Making Machine

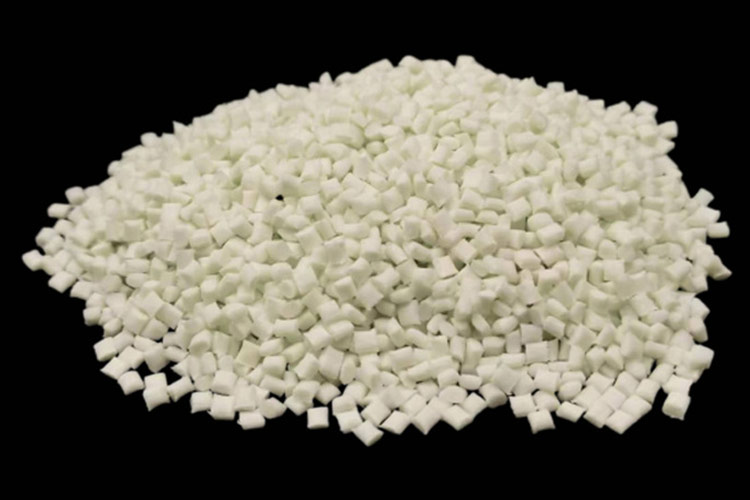

PET is a thermoplastic with high transparency and good mechanical strength. It is widely used in drinking water bottles. It features excellent impact resistance and chemical stability, effectively ensuring the safety and durability of the bottle body. In addition, PET material is lightweight, easy to handle and recycle, making it a better choice in terms of environmental performance.

PC is a hardened plastic with extremely high strength and heat resistance. It can withstand high temperature and impact. It is suitable for manufacturing 5 gallon bottle that requires higher durability. The pure water bottle made of PC material can be reused many times without easy deformation.

Product Applications of 5 Gallon Bottle Making Machine

How to Use 5 Gallon Bottle Making Machine?

Raw material preparation

Feed plastic raw materials like PET or PC

Heat and soften the raw material

Preform forming

Form the preform through molds

Create a plastic blank with a preliminary shape

Blow molding

Blow up the plastic blank by compressed air

Closely adhere to the inner wall of mold

Cooling and demolding

Use cooling system to solidify and shape

Remove the bottle from the mold

Our Services for 5 Gallon Bottle Making Machine

Customization

We offer tailor-made solutions for 5 gallon bottle making machine to meet your production requirements. Not only for adjusting equipment production capacity or automation degree, but also integrating with current production line, our professional team will design and deliver the machine which fully meets your operating goals and budget.

After-sales service

We offer comprehensive after-sales service to ensure the stable and efficient operation of your 5 gallon bottle making machine. From equipment installation and operation training to regular maintenance and timely technical support, we provide full assistance to minimize downtime and enhance equipment performance to the greatest extent.

Inquiry for 5 Gallon Bottle Making Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.