Two-Stage Blow Molding Machine Introduction

Working Process of Two-Stage Blow Molding Machine

- Raw material preparation

The raw materials for the two-stage bottle blow molding machine mainly include PP, PE, PET and other materials. These materials need to undergo thorough screening, blending, feeding, melting and other treatments before entering the production process. In order to ensure the quality and grade of raw materials, strict testing and control are required. - Injection Molding

During the injection molding process, raw materials which have been strictly selected and mixed need to be injected into the injection molding machine. After being heated, melted and plasticized, they are injected into the mold for molding. This process requires strict control of parameters such as the temperature, pressure and injection speed of the machine. - Preheating

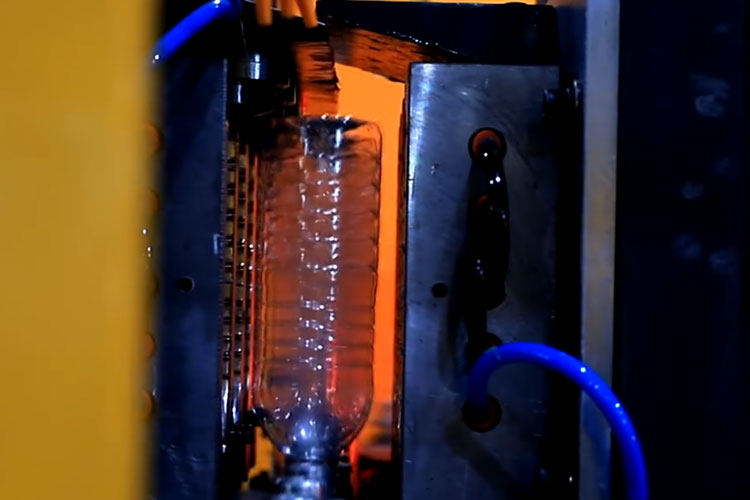

After injection molding, the molded products need to be preheated. During this process, the temperature of the preform will be uniformly raised, especially in the thickness area of the preform wall. The purpose of this process is to enhance the plasticity and flexibility of the molded products and prepare them for subsequent blow molding. - Blow molding

During the blow molding stage, the preheated molded products need to be placed into the blow molding machine for blow molding. The machine heats the molded products and then stretch them, blow air to eventually shape them into various forms of bottles. This process requires precise control over all parameters of the machine and the quality of the formed products.

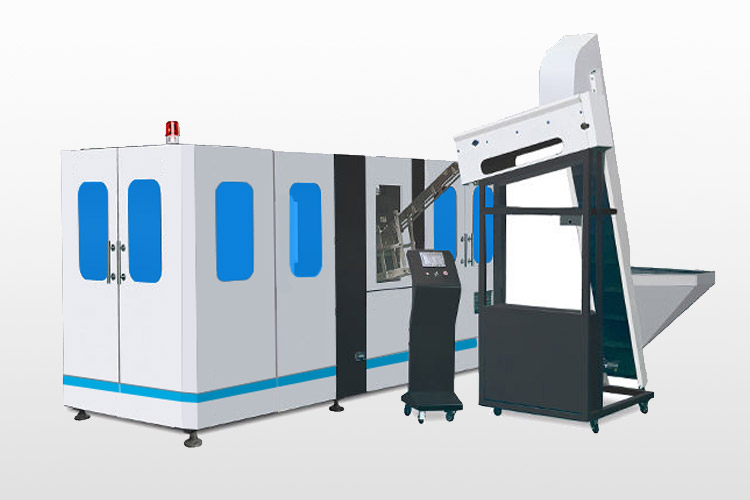

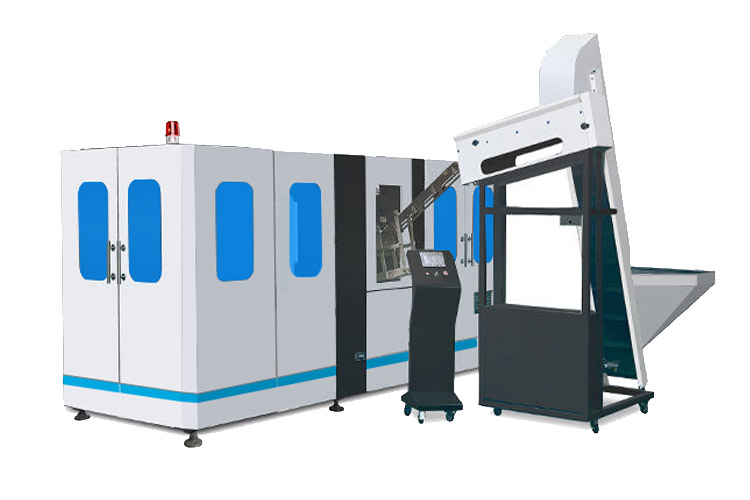

Two-Stage Blow Molding Machine Overview

Two-Stage Blow Molding Machine Installation Cases

Two-Stage vs. Single-Stage Blow Molding Machine Compariso

-

Two-Stage Blow Molding Machine

Principle: Steps are completed by two machines.

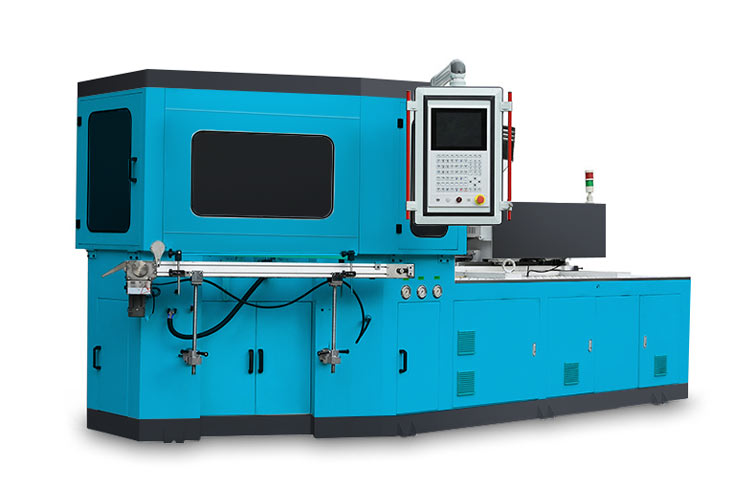

Step 1: Injection molding of the preform

The preform is produced by injection molding machine and can be cooled, stored or transported.

Step 2: Blow molding

The preform is preheated and then sent to the blow molding machine for stretching and blow molding to form plastic bottle.Features: The preform and the blow molding process are separated, offering high production flexibility. Preform can be mass-produced and supplied, making it highly suitable for large-scale centralized production.

-

Single-Stage Blow Molding Machine

Principle: Steps are completed by one machine.

Raw materials are fed into the machine at one time and the entire process of injection molding of the preform, preform heating and blow molding is completed in one machine.Features: This method eliminates the need for preform transportation and storage, reduces energy consumption. It is more suitable for the production of small batches, multiple varieties and high-precision bottle shapes.

Advantages of Two-Stage Blow Molding Machine

Raw Materials of Two-Stage Blow Molding Machin

Applications of Two-Stage Blow Molding Machine