What is Baby Feeding Bottle Machine?

Baby feeding bottle machine is an automated machine specifically designed for manufacturing baby bottles. It mainly uses injection molding and blow molding processes to shape plastic into bottles of various specifications and styles. With the continuous growth of the market demand for baby bottles, baby feeding bottle making machine integrates advanced automatic control systems and energy-efficient production technologies, greatly enhancing production efficiency and product quality. This machine usually adopts a high-precision numerical control system to achieve precise positioning and temperature control of the mold, ensuring the stability of the finished product’s dimensions and the smoothness of its appearance. Meanwhile, baby feeding bottle machine is equipped with an intelligent monitoring system that can detect various parameters during the production process in real time to ensure the safety and quality of each baby bottle. In addition, the equipment design focuses on environmental

protection and energy conservation.

It adopts low-energy consumption motors and intelligent energy-saving programs, effectively reducing production costs and environmental impact. Baby feeding bottle machine is widely used in baby product manufacturing factory. Through efficient automatic production line, this machine can mass-produce baby bottles that meet international safety standards, ensuring the products are durable and easy to clean. In the future, as the maternal and infant market continues to expand, baby feeding bottle making machine

will continue to enhance the level of automation and production efficiency, helping factory meet strict quality requirements and personalized customization demands, promoting the healthy and sustainable development of the entire baby bottle industry.

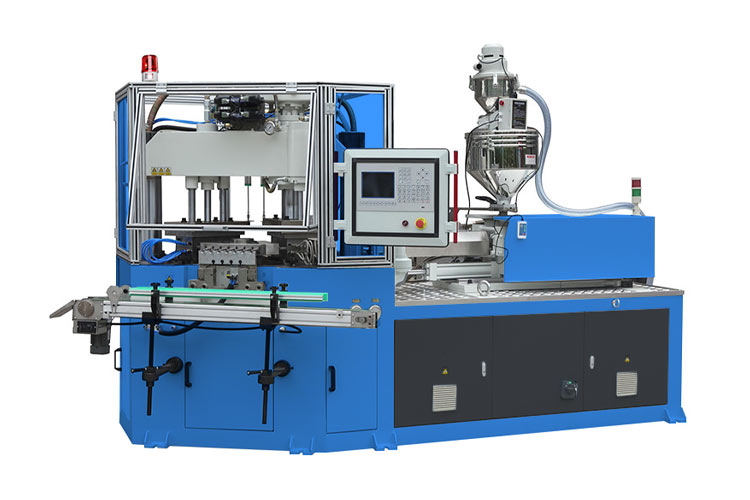

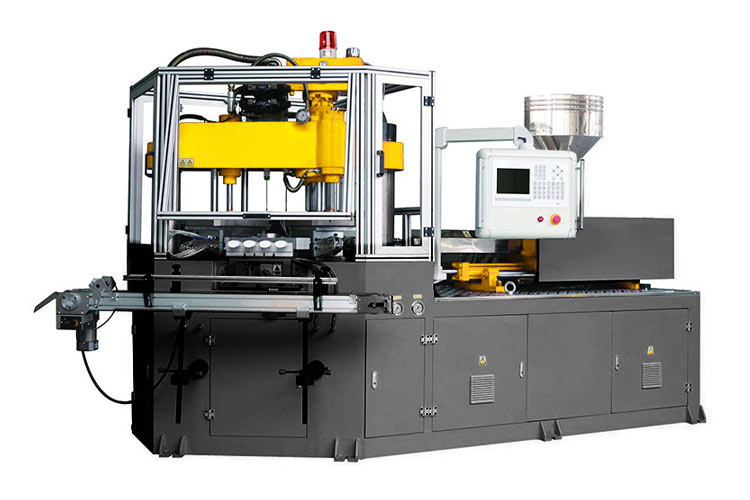

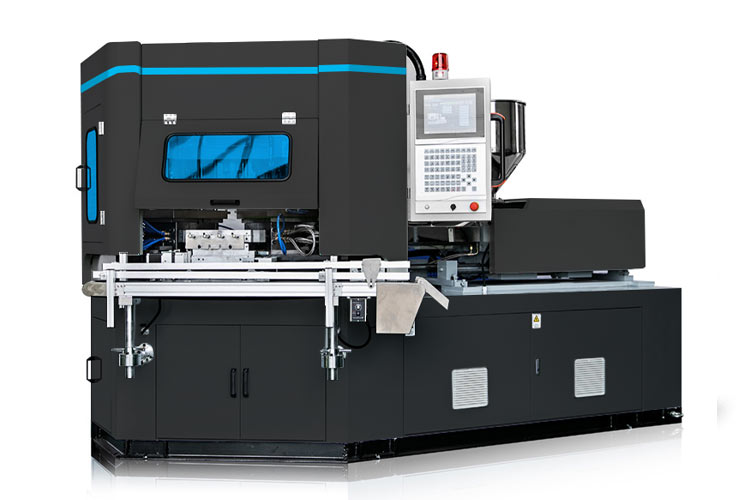

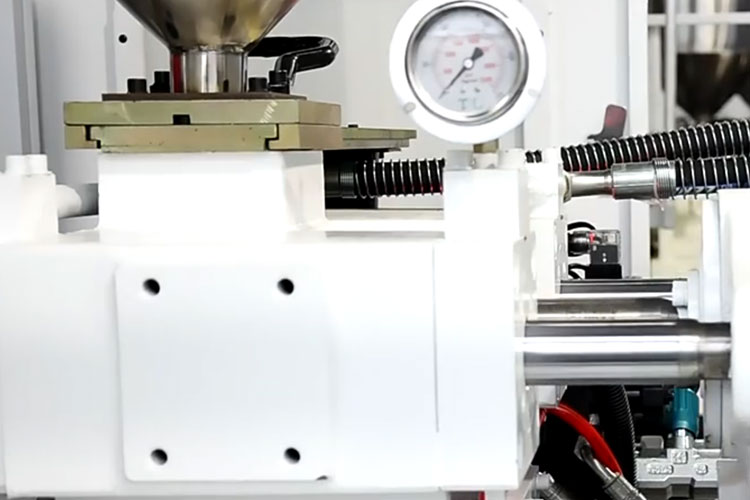

Baby Feeding Bottle Machine Overview

Baby Feeding Bottle Machine Installation Cases

Why Choose Our Baby Feeding Bottle Machine?

High-Precision Molding Technology

Food-Grade Raw Material

Fully Automatic Operation System

Energy-Saving Design

Hygienic Production Environment

User-Friendly Operation

● High-Precision Molding Technology

Baby feeding bottle machine adopt advanced injection molding and blow molding technology, ensuring the size accuracy and wall thickness consistency of the baby bottles. Therefore, the finished products will have a smooth appearance, high transparency and comfortable touch. The capacity of high-precision molding not only improve the accuracy of the bottle, but also ensure the quality of bottle.

● Food-Grade Raw Material

Baby feeding bottle machine uses food-grade raw material like PPSU, ensuring that it does not release harmful substances during high-temperature disinfection and long-term use, safeguarding the health and safety of infants. Also, the machine precisely controls the temperature and pressure to prevent the decline of material performance or the occurrence of harmful reactions.

● Fully Automatic Operation System

Baby feeding bottle machine is integrated with fully automatic operation system from feeding, injecting, blowing, cooling, molding and ejecting, achieving fully automated operation. It can not only reduce labor cost, but also avoid the risk of contamination caused by human contact. Also, it can significantly improve the efficiency of manufacturing, fulfilling large scale production demands.

● Energy-Saving Design

In the control of energy consumption, Baby feeding bottle machine adopts low-energy heating system and servo drive motor, which can reduce power consumption while ensuring production capacity. This energy-saving design not only reduces operating cost but also conforms to the concept of green and environmentally friendly production.

● Hygienic Production Environment

Baby feeding bottle machine adopts a closed cabin design, effectively isolating dust and impurities in the air and maintaining the cleanliness of the production environment, meeting the strict hygiene standards of baby bottle. Meanwhile, the machine is designed in a structure that is easy to clean and maintain, reducing the risk of bacterial growth and ensuring the hygiene and safety of the finished baby bottle.

● User-Friendly Operation

Baby feeding bottle machine is equipped with an human-machine interface (HMI) system, which can display production status, temperature, pressure and other parameters in real time. The operation interface is available in multiple languages, reducing training cost and enabling operator to master the production process proficiently in a short period of time.

Baby feeding bottle machine adopt advanced injection molding and blow molding technology, ensuring the size accuracy and wall thickness consistency of the baby bottles. Therefore, the finished products will have a smooth appearance, high transparency and comfortable touch. The capacity of high-precision molding not only improve the accuracy of the bottle, but also ensure the quality of bottle.

● Food-Grade Raw Material

Baby feeding bottle machine uses food-grade raw material like PPSU, ensuring that it does not release harmful substances during high-temperature disinfection and long-term use, safeguarding the health and safety of infants. Also, the machine precisely controls the temperature and pressure to prevent the decline of material performance or the occurrence of harmful reactions.

● Fully Automatic Operation System

Baby feeding bottle machine is integrated with fully automatic operation system from feeding, injecting, blowing, cooling, molding and ejecting, achieving fully automated operation. It can not only reduce labor cost, but also avoid the risk of contamination caused by human contact. Also, it can significantly improve the efficiency of manufacturing, fulfilling large scale production demands.

● Energy-Saving Design

In the control of energy consumption, Baby feeding bottle machine adopts low-energy heating system and servo drive motor, which can reduce power consumption while ensuring production capacity. This energy-saving design not only reduces operating cost but also conforms to the concept of green and environmentally friendly production.

● Hygienic Production Environment

Baby feeding bottle machine adopts a closed cabin design, effectively isolating dust and impurities in the air and maintaining the cleanliness of the production environment, meeting the strict hygiene standards of baby bottle. Meanwhile, the machine is designed in a structure that is easy to clean and maintain, reducing the risk of bacterial growth and ensuring the hygiene and safety of the finished baby bottle.

● User-Friendly Operation

Baby feeding bottle machine is equipped with an human-machine interface (HMI) system, which can display production status, temperature, pressure and other parameters in real time. The operation interface is available in multiple languages, reducing training cost and enabling operator to master the production process proficiently in a short period of time.

Characteristics of Baby Feeding Bottle Machine

● High-precision molding

● Safe food-grade raw material

● High-efficiency automatic production

● Multi-technology integrated design

● Eco-friendly and energy-efficient design

● Intelligent monitoring system

● Safe food-grade raw material

● High-efficiency automatic production

● Multi-technology integrated design

● Eco-friendly and energy-efficient design

● Intelligent monitoring system

IRaw Material of Baby Feeding Bottle Machine

PPSU, known as polyphenylene sulfone resinsis, is an amorphous thermoplastic. PPSU combines the advantages of polypropylene (PP) and polysulfone (PSU), featuring high heat resistance, transparency, hydrolytic stability and resistance.

Features:

Safety: PPSU does not contain Bisphenol A(BPA) or any other known harmful substances and is harmless to the health of infants.

Heat-Resistance: PPSU can withstand temperatures as high as 180 Degrees Celsius, which can be disinfected at high temperatures without generating harmful substances.

Transparency: PPSU has high-transparency, allowing users to clearly see the amount and status of milk inside the bottle, which is convenient for monitoring the progress and quantity of feeding.

Durability: PPSU baby bottle has very strong impact resistance and drop resistance which is not easy to break. In addition, this kind of bottle is relatively light in weight and convenient to carry.

Features:

Safety: PPSU does not contain Bisphenol A(BPA) or any other known harmful substances and is harmless to the health of infants.

Heat-Resistance: PPSU can withstand temperatures as high as 180 Degrees Celsius, which can be disinfected at high temperatures without generating harmful substances.

Transparency: PPSU has high-transparency, allowing users to clearly see the amount and status of milk inside the bottle, which is convenient for monitoring the progress and quantity of feeding.

Durability: PPSU baby bottle has very strong impact resistance and drop resistance which is not easy to break. In addition, this kind of bottle is relatively light in weight and convenient to carry.

Application of Baby Feeding Bottle Machine

baby feeding bottle

infant baby food feeder

baby food bottle feeder

baby food feeder bottle

baby feeder bottle

baby bottle feeder

baby feeder bottles

bottle feeder for baby

bottle feeder for baby food

feeder bottles for baby food

feeding bottle for baby

feeding bottles for baby

How to Use Baby Feeding Bottle Machine?

Raw material preparation

High-quality, BPA-free plastic pellets (PPSU) are fed into the feeding system of the machine to ensure the safety and hygiene of products.

Heating

Plastic pellets are heated to a molten state in a precisely temperature-controlled heating system, ensuring the stable molding quality.

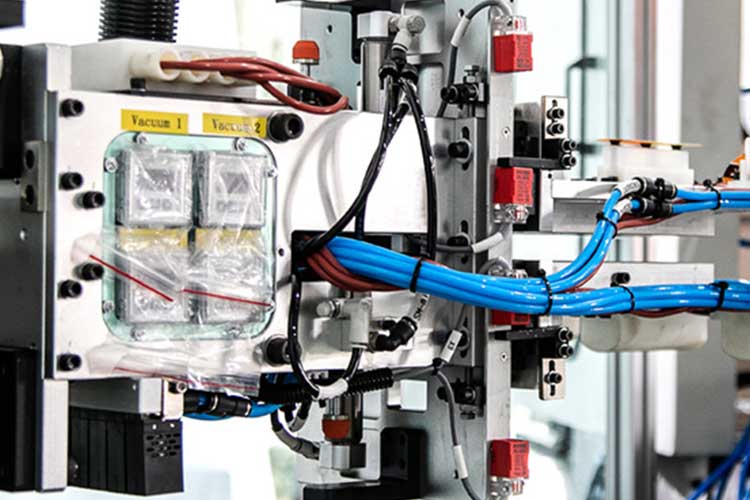

Preform forming

Molten plastic is processed into baby bottle preform through injection molding system to prepare for subsequent blow molding.

Blow molding

After being uniformly heated, the preform is inflated into the final shape of a baby feeding bottle through high-pressure air. The mold determines the capacity and appearance of the bottle.

Cooling

The formed baby bottle is rapidly cooled in the cooling system to maintain structural stability and durability.

Demolding

After the baby bottle is formed, it will automatically released and conveyed to the next process. Appearance inspection is carried out to ensure that each bottle meets the quality standards.

Inquiry for Baby Feeding Bottle Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.