What is Cosmetic Bottle Making Machine?

Cosmetic bottle making machine is a specialized equipment for manufacturing various plastic bottles and containers used in the cosmetics and personal care industries. It mainly uses advanced forming technology to transform plastic materials such as PET, PP, and PETG into bottles of various shapes and sizes. The key technologies used in cosmetic bottle making machine include injection stretch blow molding,

injection blow molding

, extrusion blow molding, etc. These technologies process plastic particles into bottles of various shapes and specifications to meet the aesthetic, sealing and functional requirements of cosmetic packaging. Meanwhile, cosmetic bottle making machine is equipped with servo drive motors, PLC control systems and mold temperature control system to ensure quality of the bottles and accuracy of production. In addition, the features of high-precision and high degree of automation enable cosmetic bottle making machine to significantly enhance production efficiency and product consistency, while reducing labor costs. It is an indispensable equipment in the modern cosmetics manufacturing industry.

Cosmetic bottle making machine can support multi-chamber production, meet the demand for large quantities and provide flexible production functions to produce different types of bottle designs, customizing shapes and sizes. Therefore, from standard cylindrical cosmetic bottles to various customized requirements, all can be fulfilled. Cosmetic bottle making machine is widely used in the beauty and personal care industries to produce high-quality plastic packaging for various product categories. From skin care and hair care to perfumes and cosmetics, the machine offers the required flexibility, speed and precision to meet diverse market demands and aesthetic preferences. It is an indispensable equipment in today’s beauty industry, playing a crucial role in connection design, functionality and production efficiency of cosmetic bottle making.

Working Process of Cosmetic Bottle Making Machine

Raw material heating

Preform forming

Heating adjustment

Mold forming

Shaping and cooling

Demolding and removal

The working process of cosmetic bottle making machine is not a single linear process, but a continuous technological flow that includes multiple stages such as raw material heating, preform forming, heating adjustment, mold forming, shaping and cooling, demolding and removal. The entire making process is monitored and coordinated throughout by a central control system like PLC and HMI, achieving functions such as automated production, parameter tracking, which enhances product consistency and production efficiency.

- Raw material heating: The plastic particles are conveyed into the heating chamber through the feeding system and heat the material to a molten state.

- Preform forming: The molten material is conveyed to the mold through the injection molding system to form a preform. Its molding quality will directly affect the mechanical properties and aesthetic appearance of the final bottle.

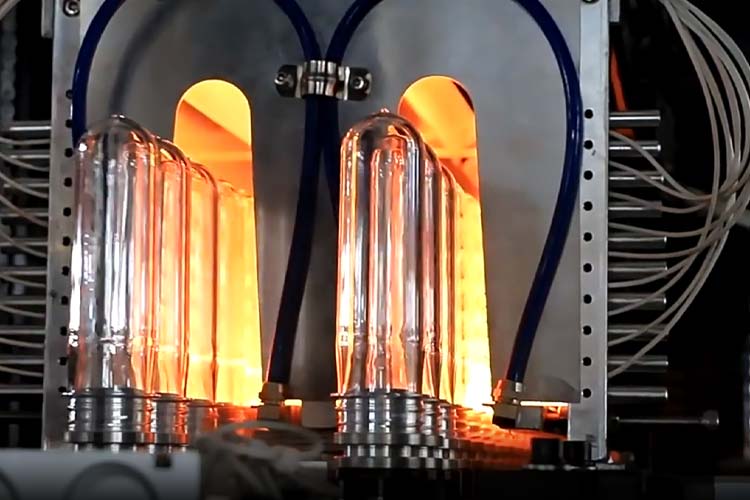

- Heating adjustment: After the preform is formed, it enters the heating module through the conveying system for preheating or temperature adjustment, with the aim of achieving an appropriate plastic state.

- Mold forming: After the mold is closed, the mechanical system controls the stretching device and the air-blowing device to work in coordination, causing the preform to rapidly expand and adhere to the mold cavity under the dual action of longitudinal stretching and transverse air pressure.

- Shaping and cooling: When the mold comes to a cooling state, the bottle is rapidly cooled to a stable structural temperature by means of circulating water or air cooling.

- Demolding and removal: The bottle is separated from the mold through the demolding system and sent out by the mechanical arm or conveyor belt.

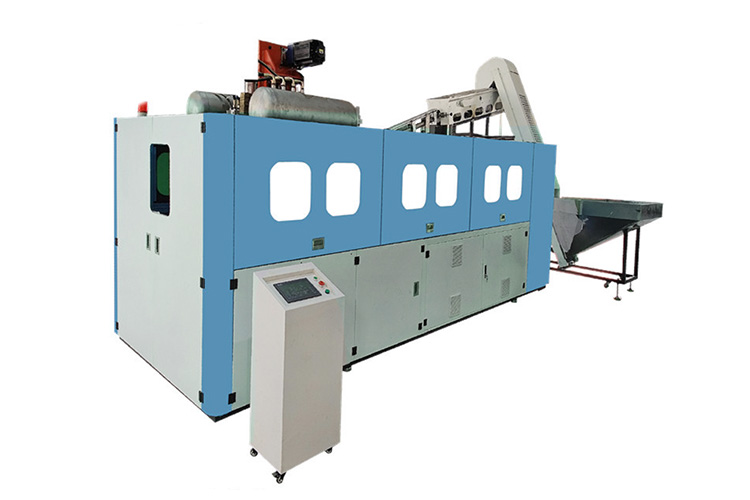

Cosmetic Bottle Making Machine Overview

Cosmetic Bottle Making Machine Installation Cases

Structure of Cosmetic Bottle Making Machine

Feeding system

Select raw material based on the requirements

Feed plastic particles like PET, PETG into the heating zone

Heating system

Preheat plastic with electric heating

Prepare for subsequent molding

Stretch blowing system

Stretched lengthwise by mechanical rod

Blow into a bottle shape through high-pressure gas

Blow into a bottle shape through high-pressure gas

Molding system

Provide precise molds based on product design

Determine the shape, capacity and appearance

Cooling system

Cool the bottle after molding

Ensure the dimensional stability and strength

Control system

Provides PLC and HMI system

Controls key parameters for fully automatic operation

Controls key parameters for fully automatic operation

Why Choose Our Cosmetic Bottle Making Machine?

- Adopt advanced automation technology

- Compatible with various raw materials

- Achieve high-precision and stable production

- Provide intelligent control system

- Simply operate and less manual intervention

- Support various shape types of bottle

- Design for eco-friendly production process

- Offer tailor-make solution for bottle

What Types of Raw Material Can Be Used in Cosmetic Bottle Making Machine?

PET

PS

PP

PE

Tritan

PEN

PC

PETG

The raw materials of cosmetic bottles are diverse, including PET, PS, PP, PE, Tritan, PEN, PC. To produce products with higher requirements, more advanced materials such as PETG may be selected. The selection of these materials mainly depends on the wall thickness, function and special requirements of the bottle.

Applications of Cosmetic Bottle Making Machine

Lotion bottle

Cream bottle

Perfume bottle

Essence bottle

Serum bottle

Spray bottle

Nozzle bottle

Airless bottle

Sample bottle

Toner bottle

Pump Bottle

Squeeze Bottle

Customization of Cosmetic Bottle Making Machine

Cosmetic Bottle Making Machine

offer comprehensive customized service and solution.

Provide Flexible production line setup

Support various raw materials

Achieve multi-molds replacement

Provide technique support and training service

Inquiry for Cosmetic Bottle Making Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.