LED Lamp Cover Making Machine

LED lamp cover making machine provide LED lamp cover manufacturing.

What is LED Lamp Cover Making Machine?

LED lamp cover making machine is a type of industrial equipment specifically designed for the production of LED lamp cover. It is mainly used for forming the lampshade structure outside of bulb and is suitable for the efficient molding of thermoplastic materials such as polycarbonate (PC) and acrylic (PMMA). With the wide application of LED lighting technology, LED lamp has higher requirements for appearance consistency, optical performance and production efficiency. Traditional manual or semi-automatic production methods of LED lamp over have gradually failed to meet the demands of modern industrialization and automation. Therefore, equipped with efficiency, LED lamp cover making machine has become the key for lamp manufacturing factories to enhance their core competitiveness. It is particularly suitable for spherical lamp cover with high requirements for batch consistency in production. In addition, LED lamp cover making machine has undergone targeted optimizations in aspects such as mold cavity structure, injection molding procedures and cooling efficiency, which can better meet the strict requirements of lamp cover products in terms of optical diffusion and dimensional consistency.

With the rapid advancement of LED technology worldwide, bulb lamp, as a entry-level lighting products, is widely used in various lighting environments such as home, office and commercial setting. Meanwhile, the design of LED lamp cover is increasingly moving towards aesthetics and intelligence. It also brings a broad space for product upgrading and customization to LED lamp cover making machine. With the continuous evolution of technology and the sustained expansion of market demand, this machine is developing towards a smarter and greener direction, playing an increasingly important role in the global LED technology industry chain.

LED Lamp Cover Making Machine Overview

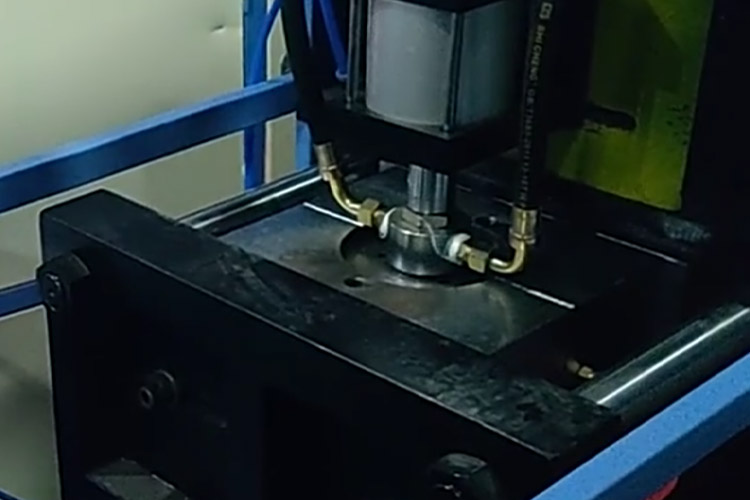

LED Lamp Cover Making Machine Installation Cases

Characteristics of LED Lamp Cover Making Machine

Provide fully automated control operation

Adopt eco-friendly servo-driven system

Easy to operate and maintain conveniently

Support multiple lamp cover designs

Compatible with multiple raw materials

Support multi-cavity mold configurations

Adopt eco-friendly servo-driven system

Easy to operate and maintain conveniently

Support multiple lamp cover designs

Compatible with multiple raw materials

Support multi-cavity mold configurations

Key Technologies of LED Lamp Cover Making Machine

Injection molding technology

It is the core technology of LED lamp cover making machine. By heating and melting thermoplastic and injecting it under high pressure into a special mold, it can be rapidly formed into spherical structure. This process has the advantages of one-time molding, high precision of finished products and fast production speed.

It is the core technology of LED lamp cover making machine. By heating and melting thermoplastic and injecting it under high pressure into a special mold, it can be rapidly formed into spherical structure. This process has the advantages of one-time molding, high precision of finished products and fast production speed.

Intelligent temperature control system

Temperature control directly affects the fluidity of plastics and surface quality of finished product. LED lamp cover making machine is equipped with high-precision heater and mold temperature control unit, which control the temperature of the barrel and the mold to ensure uniform of the material and avoid defects such as shrinkage and bubble.

Temperature control directly affects the fluidity of plastics and surface quality of finished product. LED lamp cover making machine is equipped with high-precision heater and mold temperature control unit, which control the temperature of the barrel and the mold to ensure uniform of the material and avoid defects such as shrinkage and bubble.

Injection molding technology

It is the core technology of LED lamp cover making machine. By heating and melting thermoplastic and injecting it under high pressure into a special mold, it can be rapidly formed into spherical structure. This process has the advantages of one-time molding, high precision of finished products and fast production speed.

It is the core technology of LED lamp cover making machine. By heating and melting thermoplastic and injecting it under high pressure into a special mold, it can be rapidly formed into spherical structure. This process has the advantages of one-time molding, high precision of finished products and fast production speed.

Intelligent temperature control system

Temperature control directly affects the fluidity of plastics and surface quality of finished product. LED lamp cover making machine is equipped with high-precision heater and mold temperature control unit, which control the temperature of the barrel and the mold to ensure uniform of the material and avoid defects such as shrinkage and bubble.

Temperature control directly affects the fluidity of plastics and surface quality of finished product. LED lamp cover making machine is equipped with high-precision heater and mold temperature control unit, which control the temperature of the barrel and the mold to ensure uniform of the material and avoid defects such as shrinkage and bubble.

What Types of Raw Material Can Be Used in LED Lamp Cover Making Machine?

LED lamp cover making machine mainly uses high-quality thermoplastic plastics as raw materials like polycarbonate (PC) and acrylic (PMMA). Due to their outstanding light transmittance and heat resistance, these two materials have become the preferred choice for manufacturing high-quality LED lamp cover.

Polycarbonate (PC) is a thermoplastic with excellent transparency, high impact strength and heat resistance. These characteristics make PC an ideal material for manufacturing LED lamp cover. In bulb lamp, PC lamp cover can provide good light transmittance while maintaining a sturdy and durable structure. It can also effectively resist deformation and aging caused by temperature change, making it suitable for industrial and outdoor LED lamp cover.

Acrylic (PMMA) is a transparent thermoplastic with excellent processing performance and transparency. Compared with PC, PMMA has a lower cost and better processing flexibility in some aspects. In bulb lamp, PMMA can provide uniform light distribution while maintaining the lightness and beauty of the lamp cover. It is applied to household and decorative LED lamp cover. In addition, it is not easy to cause damage when lamp cover breaks, which increases the safety of use.

The selection of raw materials of LED lamp cover mainly depends on factors such as design requirements, cost budget and usage environment. Materials of PC and acrylic are widely used in the manufacturing of LED lamp cover due to their respective advantages.

| Features | Plastic LED Lamp Cover | Glass LED Lamp Cover |

|---|---|---|

| Design Flexibility | Easy molded into various shape | Limit design flexibility |

| Cover Durability | High resistance and strong durability | Fragile and easy to damage |

| Production Cost | Low material and labor cost | High material and labor cost |

| Using Safety | Safe for production and user | Risk of damage |

| Cover Weight | Lightweight and easy to transport | Heavy and difficult to transport |

| Environmental Impact | Recycle and eco-friendly material | High-energy consumption |

Plastic LED Lamp Cover vs. Glass LED Lamp Cover

Product Applications of LED Lamp Cover Making Machine

How to Use LED Lamp Cover Making Machine?

Raw material preparation

& pretreatment

Use PC or PMMA particles as the raw materials Dehumidify raw materias to remove moisture

& pretreatment

Use PC or PMMA particles as the raw materials Dehumidify raw materias to remove moisture

Heating

Melted into a flowing state by the rotation of heater Control temperature from overheating

Melted into a flowing state by the rotation of heater Control temperature from overheating

Injection molding

Inject molten plastic into a mold under high pressure Form the shape of bulb cover in the mold cavity

Inject molten plastic into a mold under high pressure Form the shape of bulb cover in the mold cavity

Cooling and demolding

Use water or air cooling systems to solidify plastic Demold and check the quality of finished product

Use water or air cooling systems to solidify plastic Demold and check the quality of finished product

Customization of LED Lamp Cover Making Machine

Provide fully automated control operation

Adopt eco-friendly servo-driven system

Easy to operate and maintain conveniently

Support multiple lamp cover designs

Compatible with multiple raw materials

Support multi-cavity mold configurations

Adopt eco-friendly servo-driven system

Easy to operate and maintain conveniently

Support multiple lamp cover designs

Compatible with multiple raw materials

Support multi-cavity mold configurations

Inquiry for LED Lamp Cover Making Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.