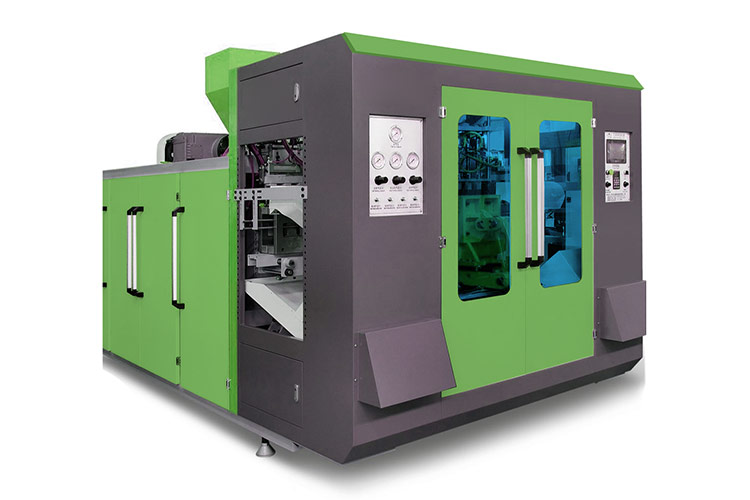

Medicine Bottle Blow Molding Machine

Medicine bottle blow molding machine focus on medical plastic injection molding.

What is Medicine Bottle Blow Molding Machine?

Medicine bottle blow molding machine is an automated forming machine specifically designed for medical bottle manufacturing. It is widely used in the production of various medicine bottles such as pill bottles, eye drop bottles, tablet bottles and disinfectant bottles. Compared with ordinary plastic bottle making machine, medicine bottle blow molding machine has higher requirements for product forming accuracy, material cleanliness and production process control. Particularly, it needs to meet strict regulations such as hygiene standard, sealing performance and physical strength for drug packaging. Medicine bottle making machine mainly heats the plastic raw materials to a molten state, controls their shape and size through molds and uses compressed air to inflate the plastic to the inner wall of the mold cavity to form the bottle body. Compared with traditional glass bottles, plastic medicine bottles are gradually replacing glass packaging due to their light weight, durability, good sealing performance and low susceptibility to contamination. They are particularly prominent in oral liquid, children’s medicine and vaccine products.

With the rapid development of the global pharmaceutical industry and the increasing emphasis on the safety of drug packaging, plastic medicine bottle making machine, as a key link in the medical packaging industry chain, is increasingly demonstrating strong application value and development potential. This machine supports long-term operation, features high production efficiency and complies with energy-saving and environmental protection design, effectively lowering energy consumption and carbon emissions. Therefore, medicine bottle blow molding machine designed in accordance with modern industrial standards not only enhances packaging efficiency but also promotes the standardization and intelligence process of the entire pharmaceutical packaging.

Working Principle of Medicine Bottle Blow Molding Machine

Medicine bottle blow molding machine mainly processes plastic raw materials into hollow medicinal plastic bottles through blow molding technology. Its working procedure is a very simple, fully automated operation. The following is the working principle of medicine bottle blow molding machine:

Raw material preparation and preforming

Medical-grade plastic raw materials such as polyethylene (PE) are added to the hopper of medicine bottle making machine and heated to a molten state through the heating system. During this process, the screw keeps rotating, pushing the molten plastic forward to be evenly mixed and plasticized. Then, the molten plastic is injected into the mold cavity to form the preform.

Medical-grade plastic raw materials such as polyethylene (PE) are added to the hopper of medicine bottle making machine and heated to a molten state through the heating system. During this process, the screw keeps rotating, pushing the molten plastic forward to be evenly mixed and plasticized. Then, the molten plastic is injected into the mold cavity to form the preform.

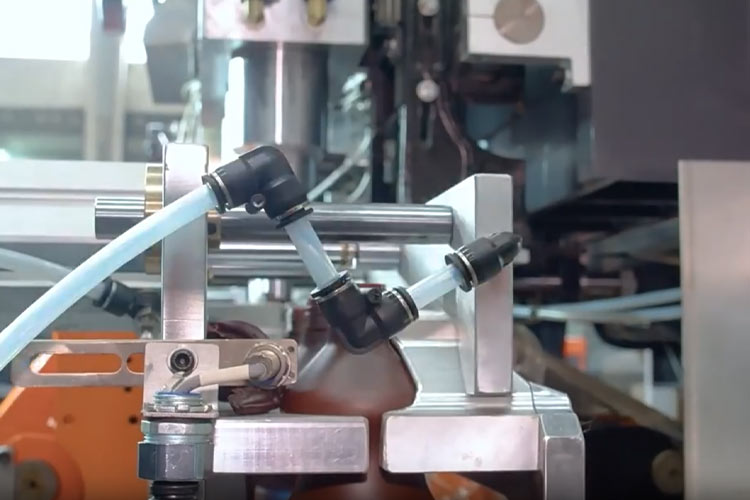

Air blow molding

When the preform is ready, the mold is closed and the preform is clamped into the mold. Then a blow rod is inserted into the interior of the preform and compressed air is injected into it at high speed. Under the action of high-pressure air flow, the preform rapidly expands and adheres to the inner wall of the mold, forming the final shape of the medicine bottle. This process requires uniform blowing and stable pressure to ensure that there are no bubbles or deformations on the bottle body.

When the preform is ready, the mold is closed and the preform is clamped into the mold. Then a blow rod is inserted into the interior of the preform and compressed air is injected into it at high speed. Under the action of high-pressure air flow, the preform rapidly expands and adheres to the inner wall of the mold, forming the final shape of the medicine bottle. This process requires uniform blowing and stable pressure to ensure that there are no bubbles or deformations on the bottle body.

Cooling and demolding

The formed medicine bottles are kept in the mold for a certain period of time to cool down and then rapidly cooled through the cooling water channels to ensure the plastic shape molding. After the cooling is completed, the automatic device takes out the formed medicine bottles for subsequent processes such as inspection and packaging.

The formed medicine bottles are kept in the mold for a certain period of time to cool down and then rapidly cooled through the cooling water channels to ensure the plastic shape molding. After the cooling is completed, the automatic device takes out the formed medicine bottles for subsequent processes such as inspection and packaging.

Medicine Bottle Blow Molding Machine Overview

Medicine Bottle Blow Molding Machine Overview

Medicine Bottle Blow Molding Machine Installation Cases

Multi-Cavity Production Capacity

Configure multi-chamber and other molds to form multiple medicine bottles at one molding, greatly improving production efficiency and fulfill the needs of large scale production.

Configure multi-chamber and other molds to form multiple medicine bottles at one molding, greatly improving production efficiency and fulfill the needs of large scale production.

Hygienic Design of Components

Adopt medical-grade stainless steel contact components and a closed structure design to ensure that the production process is dust-free and pollution-free.

Adopt medical-grade stainless steel contact components and a closed structure design to ensure that the production process is dust-free and pollution-free.

ully Automatic Operation

From feeding, heating, blow molding, cooling to bottle demolding, the process is fully automatic, combined with the PLC control system and touch operation interface

From feeding, heating, blow molding, cooling to bottle demolding, the process is fully automatic, combined with the PLC control system and touch operation interface

Support Various Materials

Adapt to various medical plastic raw materials such as PET and PP, meeting the physical and chemical compatibility requirements of different pharmaceutical packaging

Adapt to various medical plastic raw materials such as PET and PP, meeting the physical and chemical compatibility requirements of different pharmaceutical packaging

Energy-Saving Design

Adopt energy-saving heater and high-efficiency servo motor to reduce energy consumption and lower the operating costs of the equipment, making it more environmentally friendly.

Adopt energy-saving heater and high-efficiency servo motor to reduce energy consumption and lower the operating costs of the equipment, making it more environmentally friendly.

Intelligent Monitoring System

Monitor key parameters such as temperature, air pressure and mold status in real time. Once any abnormality occurs, it will automatically alarm or shut down to ensure safe operation.

Monitor key parameters such as temperature, air pressure and mold status in real time. Once any abnormality occurs, it will automatically alarm or shut down to ensure safe operation.

Why Choose Our Medicine Bottle Blow Molding Machine?

Mold

Provide high-precision mold to meet the requirements of pharmaceutical processes such as filling and sealing.

Provide high-precision mold to meet the requirements of pharmaceutical processes such as filling and sealing.

Material

Support medical-grade PET, PP and comply with the safety standards for drug packaging.

Support medical-grade PET, PP and comply with the safety standards for drug packaging.

Structure design

Place greater emphasis on the sealing performance of the bottle mouth, the uniformity of the wall thickness and the design of the anti-pollution structure.

Place greater emphasis on the sealing performance of the bottle mouth, the uniformity of the wall thickness and the design of the anti-pollution structure.

Working environment

Provide a dust-free, constant temperature and humidity environment, with anti-static and exhaust purification system.

Provide a dust-free, constant temperature and humidity environment, with anti-static and exhaust purification system.

Capacity configuration

Flexibly meet various production scale demands and ensure continuous operation without failure.

Flexibly meet various production scale demands and ensure continuous operation without failure.

Detection system

Equipped with automatic detection functions such as visual inspection, defect recognition and bottle weight detection.

Equipped with automatic detection functions such as visual inspection, defect recognition and bottle weight detection.

Application Scenarios of Medicine Bottle Blow Molding Machine

Pharmaceutical Industry

Healthcare Supplement Sector

Laboratory Consumable Industry

Veterinary Healthcare Sector

Raw Materials of Medicine Bottle Blow Molding Machine

HDPE(High-Density Polyethylene)

HDPE is the most common raw materials in medicine bottle manufacturing. It can effectively resist various corrosion of various pharmaceutical components due to the excellent chemical stability and mechanical strength. Its material is sturdy and not easily broken. Therefore, it is especially suitable for the packaging of solid medicine with high safety requirement.

HDPE is the most common raw materials in medicine bottle manufacturing. It can effectively resist various corrosion of various pharmaceutical components due to the excellent chemical stability and mechanical strength. Its material is sturdy and not easily broken. Therefore, it is especially suitable for the packaging of solid medicine with high safety requirement.

LDPE(Low-Density Polyethylene)

LDPE features softness, elasticity and low-temperature resistance, making it suitable for the production of small container that requires manual extrusion or flexible structures. In the field of pharmaceutical packaging, LDPE is often used in the manufacturing of soft bottle types such as eye drop bottles and nasal drop bottles.

LDPE features softness, elasticity and low-temperature resistance, making it suitable for the production of small container that requires manual extrusion or flexible structures. In the field of pharmaceutical packaging, LDPE is often used in the manufacturing of soft bottle types such as eye drop bottles and nasal drop bottles.

PP(Polypropylene)

PP is a plastic material that combines high-temperature resistance and chemical resistance, which is widely used in the production of pharmaceutical container that requires high-temperature sterilization or hot filling. Its transparency is moderate and can be clearly observed on the bottle body. It is often used for packaging liquid medicines such as syrup bottles and oral liquid bottles.

PP is a plastic material that combines high-temperature resistance and chemical resistance, which is widely used in the production of pharmaceutical container that requires high-temperature sterilization or hot filling. Its transparency is moderate and can be clearly observed on the bottle body. It is often used for packaging liquid medicines such as syrup bottles and oral liquid bottles.

PET(Polyethylene Terephthalate)

PET is a thermoplastic with high transparency and excellent air tightness. It is often used to make transparent medicine bottle, such as vitamin water bottle and nutrient solution bottle. Its appearance is smooth and the texture is excellent. At the same time, it has the ability to resist penetration and deformation, effectively protecting the active ingredients.

PET is a thermoplastic with high transparency and excellent air tightness. It is often used to make transparent medicine bottle, such as vitamin water bottle and nutrient solution bottle. Its appearance is smooth and the texture is excellent. At the same time, it has the ability to resist penetration and deformation, effectively protecting the active ingredients.

Product Applications of Medicine Bottle Blow Molding Machine

Syrup bottle

Eye drop bottle

Nasal spray bottle

Sample bottle

Reagent bottle

Antiseptic bottle

Deworming liquid bottle

Ear drop bottle

How to Order Medicine Bottle Blow Molding Machine?

Communication for details

Mold design and confirmation

Mold and machine production

Machine testing and inspection

Package and machine delivery

Machine installation and operation

Inquiry for Medicine Bottle Blow Molding Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.