What is Plastic Bottle Preform?

Plastic bottle preform usually refers to the original formed part of a plastic bottle, which looks like a test tube. It is a semi-finished product formed by filling raw materials into molds under specific temperature and pressure. Through blow molding processing, they can be made into packaging container such as plastic bottle. Plastic bottle preform is usually stored and transported in simple bottle shapes, waiting for subsequent processing steps. As an important intermediate product in the production of plastic bottle, the quality of preform has a significant impact on the final plastic bottle product.

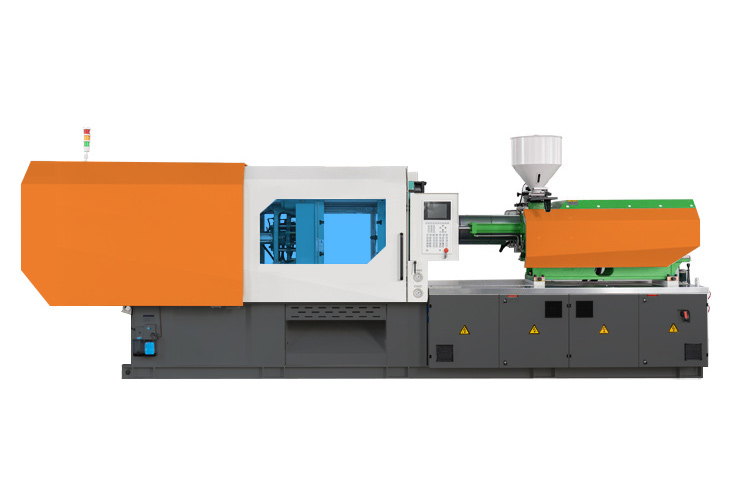

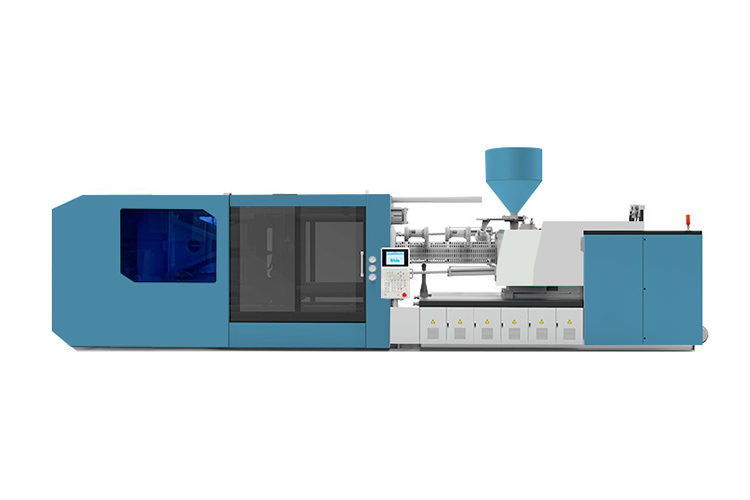

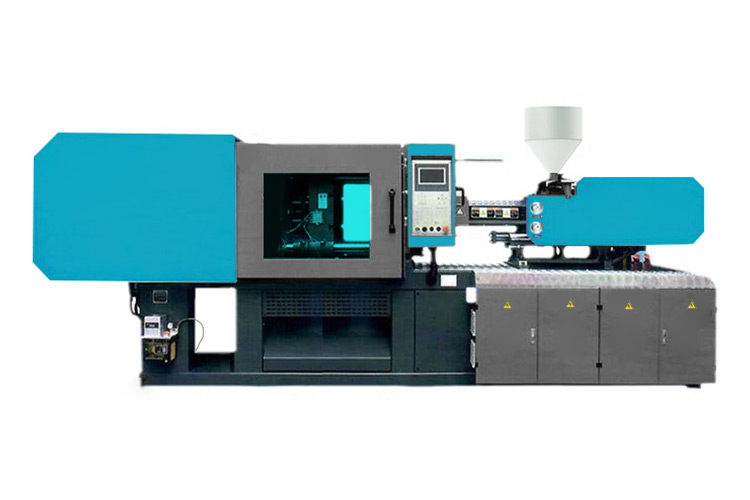

Introduction to Plastic Bottle Preform Machine

Plastic bottle preform machine, also known as bottle preform making machine, plastic preform making machine, is a kind of injection molding equipment specifically used for the production of plastic bottle preforms. As an intermediate product in the plastic bottle production process, the quality and molding accuracy of the preform directly determine the appearance, mechanical properties and service life of the final bottle. Therefore, the forming process of the plastic bottle preform is of crucial significance to the entire plastic bottle production line. Through the injection molding process, plastic bottle preform machine melts thermoplastic raw materials such as PET and injects them into special molds. After cooling, it forms preform products with consistent shapes and precise dimensions, providing stable raw materials for the subsequent blow molding process.

Bottle preform making machine is widely used in the preform manufacturing fields of multiple industries such as beverage, food, chemical and pharmaceutical. It is not only one of the core equipment in the modern plastic packaging industry, but also an important support for promoting the intelligent manufacturing upgrade of plastic containers. Meanwhile, with the enhancement of environmental awareness and the advancement of technology, plastic bottle preform machine is also constantly evolving towards higher efficiency, energy conservation and environmental protection. Through continuous technological innovation and market expansion, plastic bottle preform machine will play a more important role in the future.

Plastic Bottle Preform Machine Overview

Plastic Bottle Preform Machine Installation Cases

Working Principle of Plastic Bottle Preform Machine

The entire working process of plastic bottle preform machine

is short in time and high-efficient, making it suitable for large scale production of plastic bottle preforms. Its working principle mainly includes the following steps:

Plastic particle heating

Plastic particles are fed into the barrel through feeding system and heated into molten condition by heating system.

Plastic particles are fed into the barrel through feeding system and heated into molten condition by heating system.

Molten plastic injection

Under the push of the screw or piston, the molten plastic is injected in to the mold cavity with high pressure and high speed.

Under the push of the screw or piston, the molten plastic is injected in to the mold cavity with high pressure and high speed.

Cooling and molding

Cool the molten plastic in mold to form a plastic preform with a certain shape and size.

Cool the molten plastic in mold to form a plastic preform with a certain shape and size.

Demolding and subsequent processing

After the preform is completely cooled, the formed preform can be automatically removed through the mold opening mechanism and then process treatment like inspection and packaging.

After the preform is completely cooled, the formed preform can be automatically removed through the mold opening mechanism and then process treatment like inspection and packaging.

Key Components of Plastic Bottle Preform Machine

Feeding system

Raw material like PET is conveyed stably, continuously and efficiently from storage container to the barrel of the plastic bottle preform machine , providing raw material guarantee for the subsequent heating and melting.

Raw material like PET is conveyed stably, continuously and efficiently from storage container to the barrel of the plastic bottle preform machine , providing raw material guarantee for the subsequent heating and melting.

Injection system

It is the core component of the plastic bottle preform machine, responsible for heating and plasticizing raw material of plastics. After that, the molten plastics are injected into the mold cavity by certain pressure and speed.

It is the core component of the plastic bottle preform machine, responsible for heating and plasticizing raw material of plastics. After that, the molten plastics are injected into the mold cavity by certain pressure and speed.

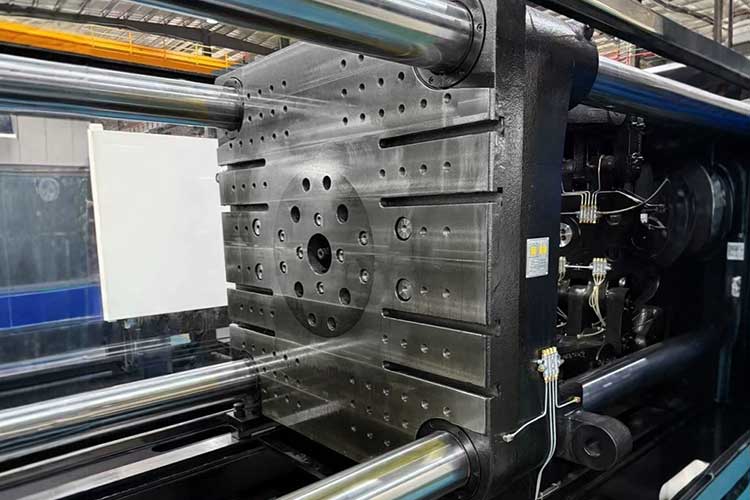

Clamping system

It is mainly responsible for ensuring that the mold can be closed, opened smoothly and the product can be ejected. When the mold is closed, it will provide sufficient clamping force to resist the cavity pressure generated, ensuring the quality of the product.

It is mainly responsible for ensuring that the mold can be closed, opened smoothly and the product can be ejected. When the mold is closed, it will provide sufficient clamping force to resist the cavity pressure generated, ensuring the quality of the product.

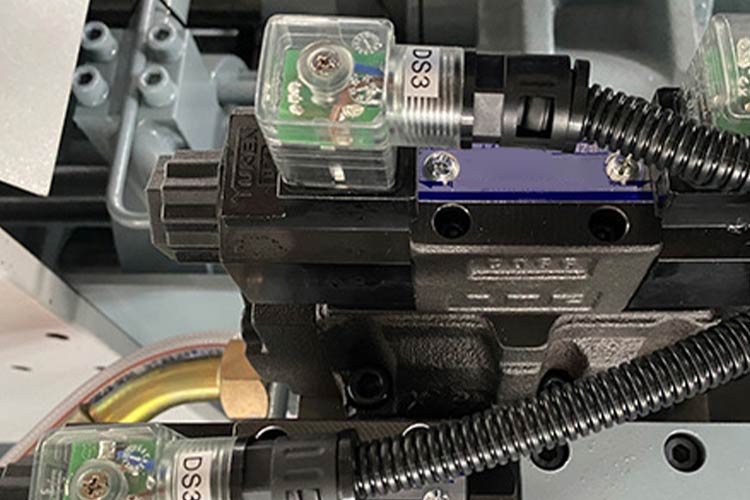

Electrical control system

It ensures the machine which can meet various requirements in the process including pressure, temperature and time control, as well as the execution of various preset programs, providing a fully automatic control mode to meet different production needs.

It ensures the machine which can meet various requirements in the process including pressure, temperature and time control, as well as the execution of various preset programs, providing a fully automatic control mode to meet different production needs.

Heating and cooling system

Heating system provides necessary heat for barrel and injection nozzle. The barrel is usually equipped with electric heating rings. Cooling system is used to reduce the temperature of barrel, nozzle and mold to prevent overheating or deforming.

Heating system provides necessary heat for barrel and injection nozzle. The barrel is usually equipped with electric heating rings. Cooling system is used to reduce the temperature of barrel, nozzle and mold to prevent overheating or deforming.

Safety monitoring system

It is composed of numerous detection elements which together form an interlock protection system that integrates electrical and mechanical systems. Once any abnormality is detected, it will immediately activate the indication or alarm mechanism.

It is composed of numerous detection elements which together form an interlock protection system that integrates electrical and mechanical systems. Once any abnormality is detected, it will immediately activate the indication or alarm mechanism.

Features of Plastic Bottle Preform Machine

Provide fully-automated production

Apply for various types of preform

Easy to operate and maintain

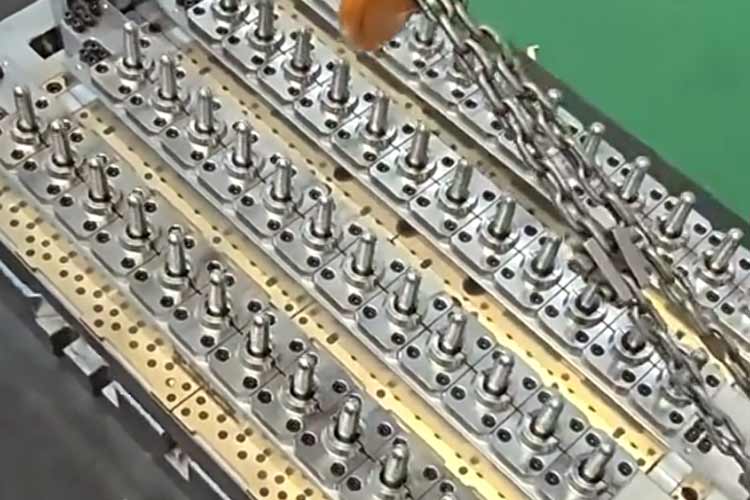

Support multi-cavity production

Adopt stable clamping system

Ensure eco-friendly processing

Provide high-precision molds

Ensure safety with monitoring system

Ensure safety with monitoring system

Raw Materials Used for Plastic Bottle Preform Machine

PET is the most common preform material, featuring high transparency, high strength and good gas barrier property. It is widely used in beverage bottle and food bottle. PC has strong impact resistance and high transparency. It is often used in the production of preform for water bottle. PP has excellent thermal stability and heat resistance. It is used in container that requires hot filling such as medicine bottle or seasoning bottle.

PET

PC

PP

Application Scenarios of Plastic Bottle Preform Machine

Pharmaceutical Industry

Food Packaging Industry

Chemical Industry

Products Made by Plastic Bottle Preform Machine

plastic bottle preform

plastic preform bottle tubes

plastic bottle preforms

preform water bottle

preform for bottles

plastic preforms

preform bottle

bottle preform

preform bottles

bottle preforms

preform for bottle

preform of bottle

Inquiry for Plastic Bottle Preform Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.