What is Plastic PET Bottle Making Machine?

Working Process of Plastic PET Bottle Making Machine

2. Injection molding: Molten plastic is processed into preforms through injection molding system. The preform is then placed in a heating system for uniform heating to reach an appropriate temperature, preparing for the subsequent blow molding process.

3. Blow molding: During the blow molding stage, the preform is placed in a mold and inflated into the desired bottle shape through high-pressure air.

4. Cooling and demolding: The formed bottle is rapidly cooled and shaped through a cooling system. Then, it is automatically released and conveyed through the conveying system to enter the subsequent inspection and packaging process.

Plastic PET Bottle Making Machine Overview

Plastic PET Bottle Making Machine Installation Cases

Core Systems of Plastic PET Bottle Making Machine

Plastic PET bottle making machine mainly consists of core components such as the heating and plasticizing system, injection molding system, preform heating system, blow molding system, cooling and shaping system, automatic control system.

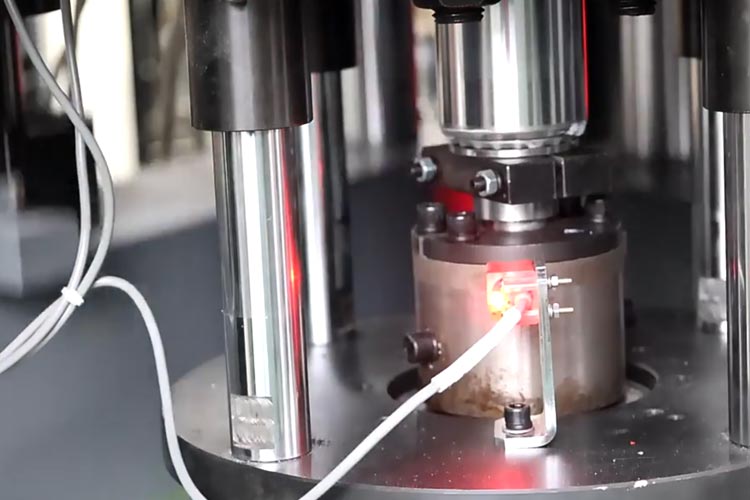

Heating and plasticizing system: PET particles are automatically fed into the machine and melted by a precisely temperature-controlled heating unit.

Injection molding system: The machine adopts injection molding technology, which processes molten PET particles into preform.

Preform heating system: The preform is heated to the optimal temperature for blowing to avoid distortion and ensure consistent thickness of the bottle walls.

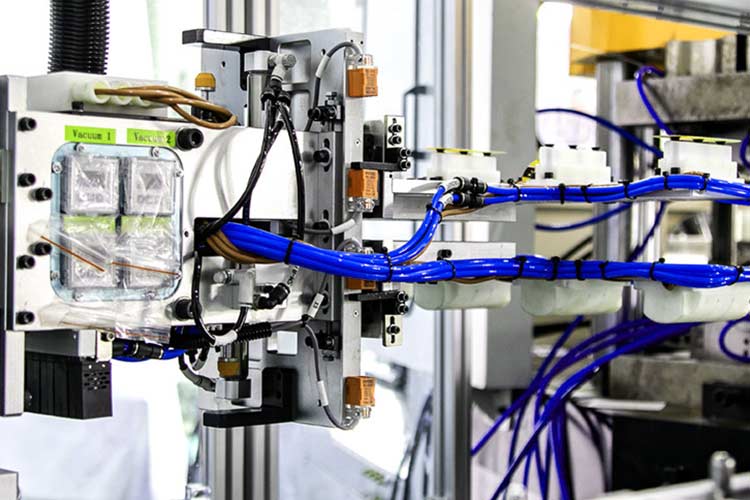

Blow molding system: In a precision mold, high-pressure air is used to inflate the preform into bottle of the required shape and volume.

Cooling and shaping system: The finished bottle is rapidly cooled to ensure the structure stability and mechanical strength.

Automatic control system: Through PLC or touch screen can monitor and adjust the key parameters like temperature, pressure, production cycle for production consistency.

Why Choose Our Plastic PET Bottle Making Machine?

Structural design for PET: The entire process is optimized and adapted to the characteristics of PET. From heating, plasticizing to blow molding, every step has been precisely optimized to fully leverage the advantages of PET in terms of transparency, strength and safety.

Multi-cavity molds: The machine supports multi-cavity molds and various automation configurations, meeting the expansion needs of different production capacity levels while maintaining high-precision injection molding and low defect rates.

Easy to use and maintain: The machine has a compact structure with standardized components. It is convenient for maintenance and repair, reducing downtime and maintenance costs.

Fully automated system: The entire process is controlled by PLC and equipped with functions such as automatic feeding, automatic demolding and automatic conveying, reducing manual intervention and lowering labor costs.

Eco-friendly design: The machine adopts energy-saving heating technology and recycling systems. Energy consumption and waste generation are reduced, which is in line with the concept of green production.

Integrated turnkey service: We provide integrated service covering solution design, machine manufacturing, installation, staff training and after-sales maintenance. We will tailor the best PET bottle production solution based on production needs.

Raw Material of Plastic PET Bottle Making Machine

PET is a common plastic material, which is widely applied in various fields due to its outstanding performance. The following are six significant characteristics of PET:

- Excellent folding endurance: Its impact strength is 3 to 5 times that of other films, which endows it with outstanding folding endurance.

- Wide solvent adaptability: It can withstand most solvents such as oil, fat, dilute acid and dilute alkali, demonstrating its wide adaptability.

- Excellent heat-aging resistance: It not only has excellent heat aging resistance. It is not easy to burn, with a yellow flame and oil dripping when burning.

- Low gas permeability: It features low gas and water vapor permeability, which makes it perform exceptionally well in blocking gases, water, oil and odors.

- High transparency and UV blocking property: It has high transparency which can effectively block ultraviolet rays. Also, PET has quite good luster.

- Outstanding hygiene and safety: PET plastic is non-toxic and odorless. It has excellent hygiene and safety, making it highly suitable for food packaging.

Products Made by Plastic PET Bottle Making Machine