Introduction of PET Preform

PET preform is a small tube preform made of Polyethylene Terephthalate(PET) material through injection molding process. It is similar in shape to the neck and body of a bottle, but a semi-finished product for manufacturing PET plastic bottle.

Advantage of PET:

Advantage of PET:

- Smooth and lustrous surface

- Good wear resistance

- Excellent dimensional stability

- Good electrical insulation performance

- Low water absorption rate

- Chemical resistance to mild acids

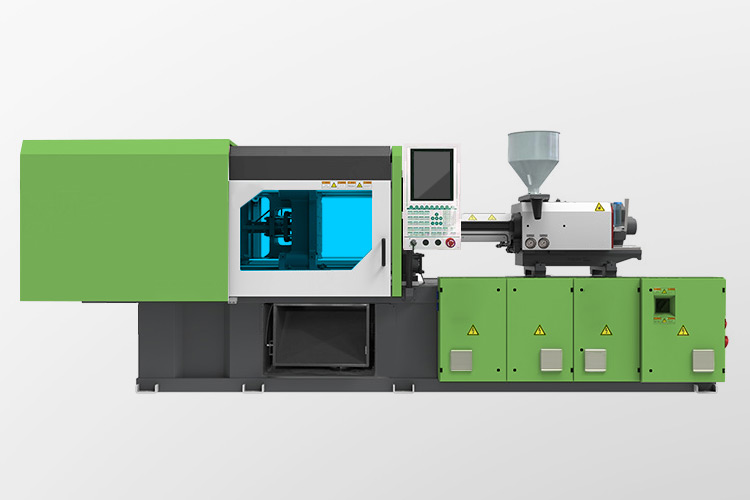

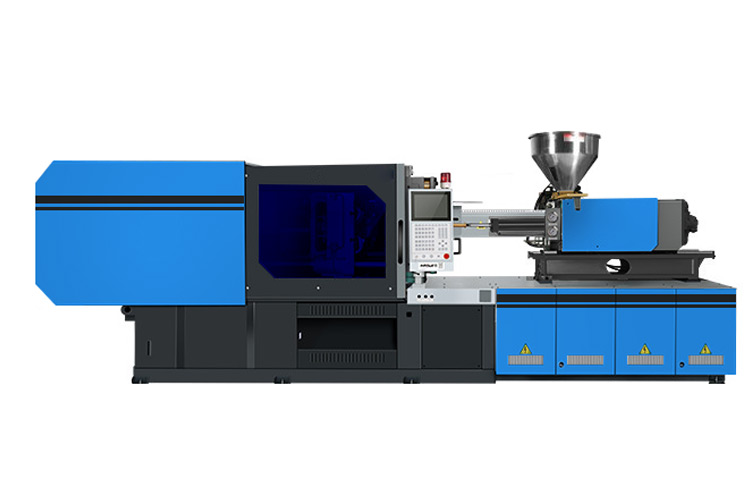

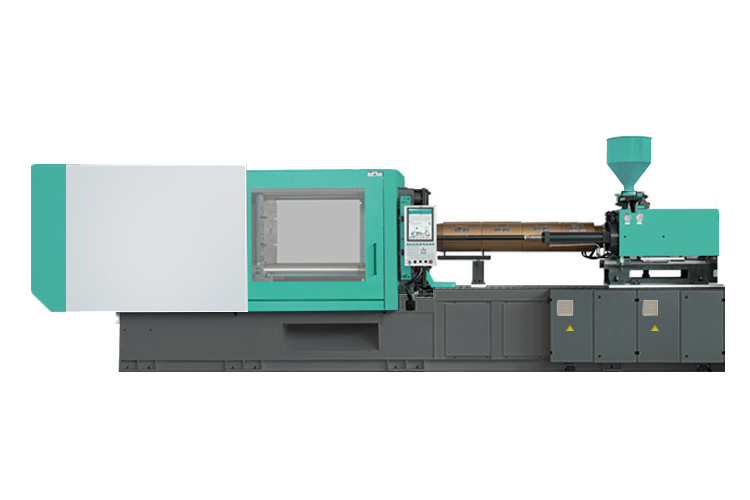

What is Preform PET Bottle Machine?

Preform PET bottle machine is a professional injection molding machine used for producing PET bottle preform. PET preform refers to the semi-finished plastic bottle made through injection molding process, which is a preliminary model similar in shape to a small test tube. PET bottle preform making machine mainly uses PET as raw material. Through high-temperature heating, PET particles are melted and plasticized, then injected into the mold cavity. After cooling and solidification, they are shaped and finally removed to form preforms. The entire process requires precise control of temperature, pressure and injection speed to ensure the dimensional accuracy and physical properties of the preform, meeting the requirements of the subsequent blow molding process. Preform PET bottle machine is usually equipped with multi-chamber molds, which can produce multiple preforms at one time, significantly improving production efficiency. The machine structure includes injection molding system,

heating system, mold system and automatic removal device.

Modern equipment is also equipped with a PLC control system to achieve automatic monitoring and parameter adjustment of the production process.

Preform PET bottle machine is widely used in multiple industries such as beverages, food, medicine and cosmetics. It is an important machine in modern plastic packaging manufacturing. With the popularization of environmental protection concepts and the development of plastic recycling technology, PET bottle has become the mainstream choice in the plastic bottle market due to the light weight, transparency and recyclability. Preform PET bottle machine

can ensure the production of high-quality preforms, providing high-quality raw materials for downstream blow molding machine, producing plastic bottle products that meet international standards.

Working Process of Preform PET Bottle Machine

Raw material preparation and drying

Melting and injection

Cooling and shaping

Mold opening and ejection

- Raw material preparation and drying

The production of PET preforms begins with raw materials, mainly using food-grade PET particles. These particles need to be dried before use to remove moisture, as PET is highly sensitive to moisture. Excessive moisture content can lead to defects such as bubbles and discoloration during molding. - Melting and injection

The dried PET particles are fed into the barrel of machine through the automatic feeding system and turned into a molten state. Then, the molten PET plastic is injected at high speed into the preform mold through an injection system. Molds are usually multi-cavity designed, allowing for the injection molding of multiple preforms at one time. - Cooling and shaping

After injection molding, the temperature of the preform is rapidly reduced through the cooling system when the mold is closed, allowing it to solidify and form. The cooling time and cooling uniformity directly affect the dimensional accuracy and surface quality of the preform. A reasonable cooling design can effectively reduce deformation and internal stress. - Mold opening and ejection

After the cooling is completed, the mold is opened and the ejector pin mechanism pushes out the formed preform. The PET preform is automatically sent to the next process through the conveying device. At this point, the preform has a complete shape and its dimensions meet the standards, but it is still in a semi-finished product state.

Preform PET Bottle Machine Overview

Preform PET Bottle Machine Installation Cases

Why Choose Our Preform PET Bottle Machine?

High-Efficiency & Precise Forming

High-speed, high-pressure molding

Multi-cavity mold design

Precise temperature control

Multi-cavity mold design

Precise temperature control

Energy Conservation and Environmental Protection

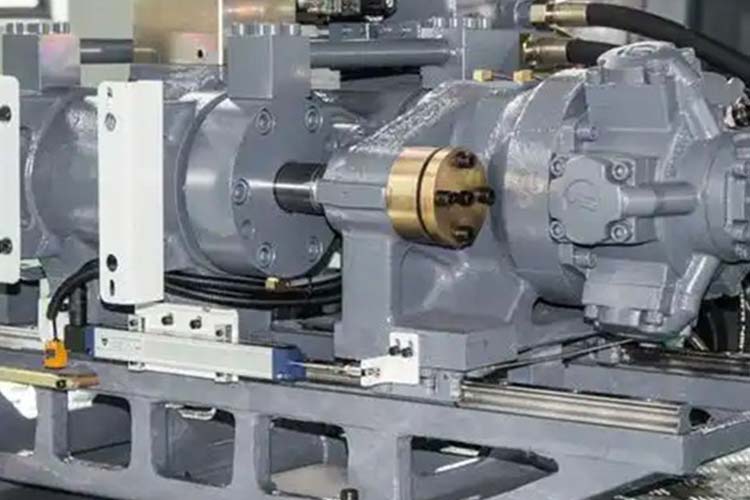

Servo motor drive system

Hot runner optimization

Waste heat recovery system

Hot runner optimization

Waste heat recovery system

Intelligence and Automation

Remote monitoring sensor

Integrated automatic quality inspection Quick mold changing system

Integrated automatic quality inspection Quick mold changing system

Ventilation Channel Design

Design for moisture removal

Surface fogging prevention

Surface consistency improvement

Surface fogging prevention

Surface consistency improvement

Applications of Preform PET Bottle Machine

Beverage Industry

Food Packaging Industry

Pharmaceutical Industry

Products Made by Preform PET Bottle Machine

Usage Precautions for Preform PET Bottle Machine

Raw material treatment

Injection system

Molds design

Injection Speed

- Raw material treatment

PET is hydrophilic. Excessive moisture can cause molecular degradation, making the product brittle and discolored. It must be thoroughly dried before processing and the recycled material should not exceed 25%. - Injection system

PET has a high melting point and a short stabilization time, so it requires multiple temperature control sections and a low-friction injection system. The weight of the product should be no less than two-thirds of the machine injection volume. - Molds design

The preform is formed by hot runner mold. A thick heat insulation board needs to be installed between the mold and the machine template. And it should be able to withstand high pressure. Venting should be sufficient to prevent local overheating or cracking. - Injection Speed

Normally, the injection speed should be fast to prevent premature solidification. But if it is over-injecting, it will broken the raw material. So, it is of great significance to control the speed of injection.

Inquiry for Preform PET Bottle Machine

We would like to hear from you. Please send us a message by filling out the form below and we will get back with you shortly.