Manufacturers often ask about the advantages and disadvantages of injection stretch blow molding. This process plays a critical role in the blow molding industry, especially for products needing high clarity and strength. Many sectors, such as beverage, food, and pharmaceutical packaging, depend on injection stretch blow molding for reliable results. The packaging industry leads in revenue share, with PET bottles for water, soda, and personal care products driving demand.

- Sales of injection stretch blow molding machine reached $1.70 billion in 2023, with rapid growth expected.

- Blow molding and blow moulding processes remain essential in packaging, offering solutions for both quality and efficiency.

Choosing the right blow molding method depends on specific production goals and industry standards.

Key Takeaways

- Injection stretch blow molding creates strong, clear, and lightweight plastic bottles by stretching the material in two directions.

- This process offers excellent control over bottle shape, wall thickness, and surface finish, making it ideal for high-quality packaging.

- High production speed and automation make injection stretch blow molding cost-effective for large-scale manufacturing.

- The initial cost and complexity of machines and molds are high, so this method suits businesses with large production volumes.

- Certain bottle shapes, like handled or irregular designs, are difficult to make with this process, so simpler shapes work best.

Injection Stretch Blow Molding Overview

Process Steps

Injection stretch blow molding uses a series of precise steps to create high-quality bottles and containers. Each step in the blow molding process shapes the final product’s strength and appearance.

- Injection Molding: The process begins by forming a preform with exact dimensions. This step ensures even material distribution, which is vital for product strength.

- Conditioning (Heating): The preform is heated to the ideal temperature. Proper heating prepares the material for stretching and aligns the polymer molecules.

- Stretching: The preform undergoes stretching, which improves both clarity and strength. This step aligns the molecules in two directions, known as biaxial stretching.

- Blowing: Air inflates the preform inside a mold. This step gives the container its final shape and ensures a smooth surface finish.

- Cooling: The product cools and solidifies, locking in its shape and mechanical properties.

Each stage in the blow moulding process controls the product’s dimensions, wall thickness, and clarity, reducing waste and improving quality.

Key Features

Injection stretch blow molding stands out among methods of plastic blow molding. The process combines injection molding and stretch blow molding, producing hollow parts with uniform wall thickness. Manufacturers often use this technique for high-volume production of bottles and containers, such as milk jugs and soda bottles. The two-stage process allows storage of preforms before blowing, which adds flexibility to the blow moulding process. Unlike standard injection molding, which creates solid parts, this method produces lightweight, strong, and clear containers. The ability to achieve consistent quality and uniformity makes it a preferred choice in the packaging industry.

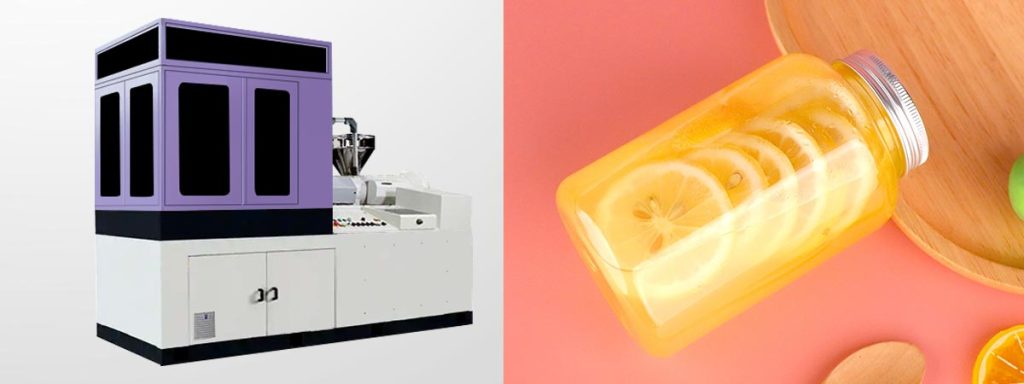

Injection Stretch Blow Molding Machine

The injection stretch blow molding machine plays a central role in production efficiency and product consistency. Its design includes advanced heating systems, stretching and blowing mechanisms, and precise molds. These features allow for accurate control over preform temperature and stretching, which leads to uniform wall thickness and reliable product quality. Modern machines use servo motors and automation to speed up production and reduce defects. Integrated quality control systems detect issues in real time, ensuring high standards. The machine’s flexibility supports quick mold changes and the use of sustainable materials, making it a key asset in modern plastic blow molding operations.

Advantages

Strength and Durability

Injection stretch blow molding creates products with outstanding strength and durability. The process stretches the preform in two directions, which aligns the polymer molecules and increases mechanical properties. PET bottles made with this method show much higher tensile strength than those produced by extrusion blow molding. This improvement allows manufacturers to use thinner walls without sacrificing durability. The resulting plastic bottles resist breakage during production, storage, and transportation. The injection stretch blow molding machine controls the stretching and blowing steps, which leads to bottles that can handle high pressure and rough handling. These advantages make this process ideal for packaging carbonated drinks and other demanding applications.

Barrier Properties

Barrier properties play a crucial role in preserving the contents of plastic containers. Injection stretch blow molding produces ISBM bottles with excellent resistance to gas transmission, especially when using PET. PET bottles have much lower oxygen and carbon dioxide permeability than polypropylene bottles. This feature helps keep beverages fresh and extends shelf life. Manufacturers can also add special barrier layers, such as EVOH or nylon, during the blow molding process. These layers block gases and protect sensitive products from spoilage. The injection stretch blow molding machine allows precise control over cooling and layer placement, which further improves barrier performance.

Clarity and Surface Finish

Clarity and surface finish set injection stretch blow molding apart from other plastic blow molding methods. The stretching process creates products with high transparency and a smooth, glossy surface. Water bottles and other clear containers benefit from this superior appearance. Injection blow molding also produces smooth surfaces, but extrusion blow molding often leaves streaks or seams. Compared to IBM machine, injection stretch blow molding machine ensures even material distribution, which results in consistent wall thickness and fewer imperfections. These qualities enhance the visual appeal and perceived quality of plastic products.

Design Flexibility

Design flexibility stands out as one of the main advantages of injection stretch blow molding. The process starts with an injection-molded preform, which allows for precise neck and thread features. Manufacturers can create complex bottle designs with uniform wall thickness and fine details. This flexibility supports innovative bottle design, such as pressure-resistant containers for fizzy drinks. Other blow molding methods struggle to achieve the same level of detail and consistency. Compared to IBM machine, injection stretch blow molding machine enables quick changes between molds, making it easier to produce a wide range of plastic products.

High Volume Capability

Injection stretch blow molding supports high production capacity, making it cost efficient for large-scale manufacturing. The process uses multi-cavity molds and automation to produce thousands of bottles per hour. The injection stretch blow molding machine maintains tight tolerances and consistent quality, even during long production runs. This efficiency reduces waste and lowers the cost per unit. Companies that need to supply millions of plastic containers each year benefit from the speed and reliability of this blow molding method.

Dimensional Accuracy

Dimensional accuracy is essential for products that require precise sealing and capping. Injection stretch blow molding achieves this by first forming a preform with exact neck and thread dimensions. The preform then moves to the blow mold, where compressed air shapes it into the final container. The use of core rods and advanced robotics ensures that each bottle matches the required specifications. The injection stretch blow molding machine cools the product quickly, locking in the shape and minimizing defects. This accuracy supports automated filling lines and reduces the need for manual inspection. Consistent dimensions also improve the overall quality of plastic blow molding products.

Injection stretch blow molding combines strength, clarity, flexibility, and efficiency, making it a top choice for producing high-quality plastic containers and bottles.

Disadvantages

Injection stretch blow molding offers many benefits, but manufacturers must also consider several disadvantages before choosing this process. These drawbacks can impact the overall feasibility and efficiency of a blow molding operation.

High Initial Cost

Setting up an injection stretch blow molding line requires a significant initial investment. The cost of machines and molds is much higher than for extrusion blow molding. The following table compares the typical costs for equipment and tooling:

| Equipment/Tooling Type | Injection Stretch Blow Molding (ISBM) Cost Range | Extrusion Blow Molding (EBM) Cost Range |

|---|---|---|

| Machines | $25,000 – $45,000 | N/A |

| Single Cavity Molds | $4,700 – $40,000 | $3,000 |

| Multi-Cavity Molds | Up to $89,500 (depending on capacity) | Up to $25,000 |

Injection stretch blow molding machine costs often exceed those of other blow molding equipment. This higher upfront expense can be a barrier for small businesses or startups. While the process delivers high efficiency and lower per-unit costs at scale, the initial outlay increases the overall production cost, especially for companies with limited capital.

Tooling Expenses

Tooling for injection stretch blow molding also adds to the total production cost. Compared to extrusion blow molding, the molds and related tools are more complex and expensive. The chart below illustrates the differences in tooling costs among common blow molding methods:

Injection stretch blow molding machine must meet strict tolerances for neck finishes and thread details. These requirements drive up costs, especially for multi-cavity molds designed for high-volume production. Although the investment pays off for large runs, it may not suit operations with frequent product changes or low-volume needs.

Space Requirements

Injection stretch blow molding machines and their supporting equipment demand considerable floor space. The process involves multiple stages, including injection, conditioning, stretching, blowing, and cooling. Each stage requires dedicated machinery and handling systems. Facilities must allocate enough room for storage of preforms, molds, and finished bottles. This space requirement can limit the process’s suitability for smaller manufacturing sites or companies with limited real estate. Large-scale blow molding operations often need to invest in facility expansion, which further increases the total production cost.

Shape Limitations

Despite its strengths, injection stretch blow molding faces several shape limitations. Certain bottle designs present challenges that can affect product quality and consistency. Common issues include:

- Handled ware needs extra material in the handle area, making it difficult to achieve uniform wall thickness without weak points.

- Oval and asymmetrical shapes often cause uneven stretching, leading to thin spots or incomplete formation.

- High stretch ratios in sharp corners, shoulders, or deep bases can result in excessive thinning and defects.

- Sharp inner corners and pinched or concave structures create stress concentrations and weak spots.

- The preform design must match the final bottle shape closely to avoid uneven material distribution.

- Complex shapes with integrated handles or concave features require advanced engineering and may not be feasible for all blow molding projects.

These limitations mean that injection stretch blow molding works best for round or slightly contoured bottles. Manufacturers seeking to produce handled ware or highly irregular shapes may need to consider other blow moulding methods.

Operational Complexity

Operating an injection stretch blow molding machine involves advanced technology and skilled personnel. The process requires:

- Precise temperature control during plasticizing to maintain optimal melt viscosity.

- Accurate injection with closed-loop pressure control for consistent shot volumes.

- Synchronization of mechanical actions between injection and blowing stages.

- Mold design and quick-change systems to reduce downtime and maintain specifications.

- High clamping forces and precise air pressure control for uniform wall thickness.

- Integration of inline vision inspection, IoT-enabled predictive maintenance, and energy-efficient hydraulic systems.

These factors increase the complexity of daily operations. Skilled technicians must monitor and adjust the process to prevent defects and maintain quality. Training and retaining qualified staff add to the ongoing production cost. If not managed well, operational complexity can reduce throughput and increase waste. However, when properly controlled, these systems improve efficiency and product quality, balancing the higher technology investment with long-term benefits.

Manufacturers must weigh these disadvantages against the advantages of injection stretch blow molding. The process suits high-volume, high-quality blow molding applications, but it may not fit every production scenario.

ISBM vs. Other Blow Molding Methods

Extrusion Blow Molding

Extrusion blow molding stands out for its ability to create the most complex shapes among all blow molding processes. Manufacturers use this method to produce a wide range of hollow products, from small bottles to large industrial parts, sporting goods, and medical products. The process involves extruding heated plastic and inflating it inside a mold. This technique allows for the formation of handles, irregular grips, and multi-layered structures. Facilities can use recycled materials in inner layers, which supports environmental goals and reduces waste. However, extrusion blow molding offers less control over wall thickness and surface finish compared to injection stretch blow molding. The process may also generate more material waste, especially when producing intricate plastic products.

Injection Blow Molding

Injection blow molding uses a different approach. It injects heated material into a mold to form a preform, then inflates the preform to create hollow products. This method excels at producing bottles with precise necks and consistent dimensions. Manufacturers often choose injection blow molding machine for pharmaceutical and cosmetic containers that require high-quality sealing and uniformity. However, this process has limitations in making complex shapes. It works best for simple, symmetrical plastic bottles and containers. The injection stretch blow molding machine offers better control over wall thickness and clarity, making it the preferred choice for clear PET bottles.

Choosing the Right Method

Selecting the best blow molding process depends on several important factors:

- Material Properties: PET works well with injection stretch blow molding due to its ability to stretch in two directions. HDPE suits extrusion blow molding for products with handles or complex shapes.

- Product Design and Complexity: Extrusion blow molding handles irregular shapes and handles. Injection stretch blow molding and injection blow molding suit simple, symmetrical designs.

- Quality Requirements: High precision and clarity favor injection stretch blow molding. Extrusion blow molding may result in rougher surfaces.

- Cost Considerations: Extrusion blow molding usually has lower equipment costs. Injection stretch blow molding and injection blow molding require higher investment in tooling and machines.

- Production Volume: High-volume production benefits from automated systems like the injection stretch blow molding machine.

- Environmental Impact: All plastic blow molding methods generate waste, but using recycled plastics and biodegradable materials can reduce harm. Injection stretch blow molding produces recyclable containers and offers efficient resource use.

Manufacturers should assess their product type, design needs, production scale, and environmental goals before choosing a blow molding process. Consulting with experts and testing different machines ensures the best fit for specific plastic products.

| Blow Molding Type | Main Application Areas |

|---|---|

| Injection Stretch Blow Molding | Primarily used for clear PET bottles such as two-liter soda bottles; allows material savings and precise bottle necks. |

| Injection Blow Molding | Used for producing bottles in large quantities; ideal for precise necks; limited in making complex shapes. |

| Extrusion Blow Molding | Suitable for the most complex shapes; used for a wide range of hollow products including small bottles, large industrial parts, sporting goods, automotive components, and medical products. |

Conclusion

Injection stretch blow molding delivers clear, strong, and precise products, making it ideal for high-end container applications. The process achieves high volume output and excellent dimensional control, but higher costs and operational complexity can limit its use in some settings. Manufacturers should assess production needs, budget, and product requirements before investing in an injection stretch blow molding machine. Consulting industry experts and reviewing standards from organizations like the FDA or ISO helps ensure the best results for specialized products.

FAQ

What Materials Work Best With Injection Stretch Blow Molding?

PET (polyethylene terephthalate) works best with injection stretch blow molding. This material provides high clarity and strength. Manufacturers often use PET with an injection stretch blow molding machine to produce bottles for beverages and personal care products.

How Does Injection Stretch Blow Molding Improve Bottle Quality?

The injection stretch blow molding machine stretches the preform in two directions. This process aligns the polymer molecules. The result is a bottle with better strength, clarity, and barrier properties compared to other blow molding methods.

Can Small Businesses Use Injection Stretch Blow Molding Machines?

Small businesses may face challenges due to the high initial cost of an injection stretch blow molding machine. This process suits large-scale production. Companies with low-volume needs often choose other blow molding methods.

What Shapes Are Difficult to Produce with Injection Stretch Blow Molding?

Handled bottles, oval shapes, and containers with sharp corners present challenges. The injection stretch blow molding machine works best for round or slightly contoured bottles. Complex shapes may require different blow molding processes.

How Does Injection Stretch Blow Molding Support Sustainability?

Manufacturers can use recycled PET with an injection stretch blow molding machine. This process reduces waste and supports environmental goals. Many PET bottles made this way are fully recyclable.