Many manufacturers encounter the following blow molding defects:

| Defect Type | Description |

|---|---|

| Uneven Wall Thickness | One side of the bottle appears thin while the other side is thick, which may cause bursting. |

| Haze and Brittleness | The bottle looks milky or hazy, making it brittle and likely to fail drop tests. |

| Leaking Necks | Caps do not seal properly due to flash or gate vestige from the ISBM molding. |

| Bottom Stress | Sharp plastic pieces create stress cracks or bottom bursts, reducing bottle integrity. |

Operators can recognize these issues by inspecting for thin walls, milky surfaces, or poorly sealing necks. Common causes include poor parison control, mold misalignment, or moisture in the resin. Proper parison programming, mold alignment, and resin drying help prevent these problems. Understanding blow molding defects improves quality control, especially for ISBM machine, and helps maintain critical properties like top-load strength.

Key Takeaways

- Identify common blow molding defects like uneven wall thickness and flash formation to improve product quality.

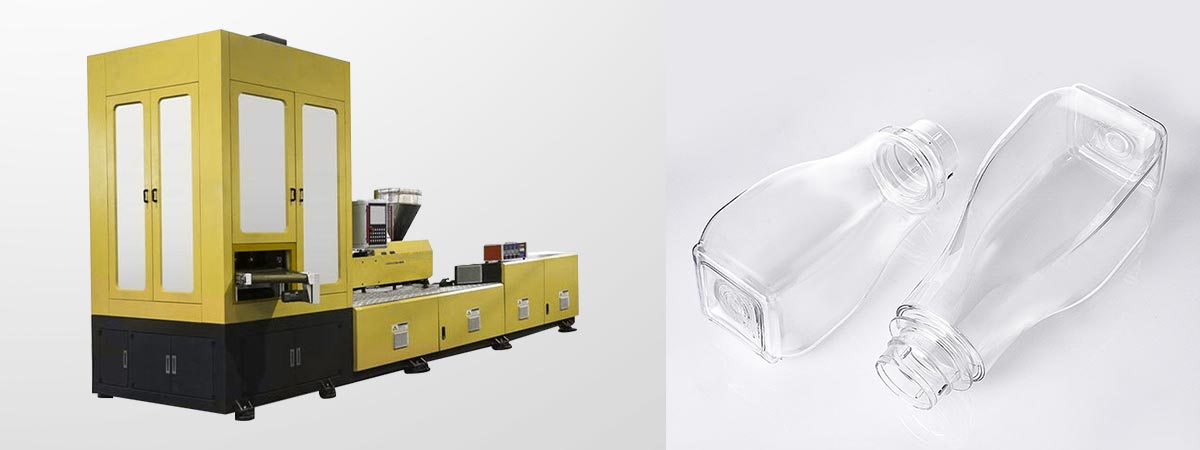

- Regularly inspect and maintain ISBM machine to prevent defects and ensure consistent production efficiency.

- Control moisture levels in resin to avoid bubbles and surface defects, enhancing the durability of blow molded products.

- Optimize machine settings, such as temperature and pressure, to improve top-load strength and reduce rejection rates.

- Implement strict quality control measures to catch defects early, reduce waste, and maintain high standards in production.

Common Blow Molding Defects

Parison Sag

Parison sag appears when the extruded tube of molten plastic, called the parison, stretches or droops under its own weight before the mold closes. This defect often leads to bottles or containers with uneven wall thickness, especially at the bottom or sides. Heavier parisons and longer extrusion times increase the risk of sagging. High melt viscosity can also make the parison less stable during the blow molding process.

Operators can recognize parison sag by inspecting for bulges or thin spots in finished products. Instability in the parison often results from improper temperature control, slow extrusion speed, or incorrect parison programming. ISBM machine plays a crucial role in preventing this defect. Proper adjustment of temperature, extrusion speed, and parison programming helps maintain parison stability.

Tip: Most modern extrusion blow molding machines use wall thickness controllers that adjust the die gap during extrusion blow molding. This technology helps counteract parison sag and ensures more uniform wall thickness.

Parison sag reduces product quality by creating weak points that may burst under pressure. It also lowers production efficiency because more products fail quality checks and require rework or scrap.

| Factor | Influence on Parison Sag |

|---|---|

| Weight of the parison | Heavier parisons sag more easily |

| Extrusion time | Longer times increase sag risk |

| Melt viscosity | High viscosity affects parison stability |

Wall Thickness Variation

Wall thickness variation is one of the most common blow molding defects. It occurs when one side of the container is thicker or thinner than the other. This defect can cause bottles to burst, leak, or fail top-load tests.

Several factors contribute to wall thickness variation:

- Bent stretch rod: A bent rod can skew the gate direction, leading to uneven wall thickness.

- Preform bending: Uneven preform wall thickness causes inconsistent heating and shrinkage.

- Uneven heating or cooling: If one side of the preform is cooler, it stretches less, resulting in thicker walls.

- Small stretch ratios: Insufficient stretching leaves some areas thicker than others.

Settings of ISBM machine, such as temperature, pressure, and cooling rates, must be optimized to prevent this defect. Incorrect settings can lead to surface imperfections and dimensional instability.

Wall thickness variation impacts both product quality and production efficiency. Containers with uneven walls may not withstand pressure or stacking, leading to higher rejection rates and increased material waste.

Note: Instability in the parison, caused by factors like extrusion speed, parison temperature, and blowing pressure, can also lead to wall thickness variation.

Flash Formation

Flash formation happens when excess plastic escapes at the mold parting line during blow molding. This defect creates thin, unwanted fins or ridges on the edges of bottles or containers. Flashing results from improper clamping pressure, worn molds, or incorrect machine settings.

Flash formation affects the dimensional accuracy of blow molded items. The excess material requires additional trimming, which increases post-processing time and costs. Trimming often involves rotary knife systems or precision cutting, especially for bottles.

To prevent flash formation, industry experts recommend:

- Clamping force optimization: Calculate and apply the correct clamping force based on mold and part geometry.

- Regular maintenance: Inspect and maintain the clamping mechanism to ensure consistent force.

- Temperature control: Keep mold temperatures uniform, avoiding differences greater than ±5°F (±2.8°C).

- Simulation software: Use simulation tools to identify and correct potential flash issues before production.

Flash formation reduces production efficiency by increasing the need for manual or automated trimming. It also raises costs and can lead to dimensional inaccuracies if not properly removed.

Flash formation not only affects the appearance of the product but also increases the risk of leaks and poor sealing, especially around the neck and base.

Blow-Outs and Surface Issues

Blow-Outs

Blow-outs occur when the molded container ruptures or develops holes during production. Operators often notice leaks or splits along the pinch-off area or thin sections of the bottle. Several factors contribute to blow-outs:

- Problems with the pinch-off, such as edges that are too sharp, too wide, or too hot.

- Low clamp pressure, which allows the mold to separate and weakens the weld.

- High blow pressure, causing the parison to stretch too quickly.

- Short parison length, which fails to fill the mold completely.

- Excessive blow-up ratio, resulting in thin walls.

- Moisture in the resin, which can compromise product strength.

Insufficient clamping pressure at the pinch-off point can result in poor welds, leading to leaks and potential blow-outs. Excessive air pressure during the blowing process may exceed the container’s strength, causing ruptures. Proper management of these parameters ensures the integrity of the molded products.

Operators can prevent blow-outs by adjusting clamp pressure, monitoring blow pressure, and ensuring the pinch-off design is correct. Regular checks for moisture in the resin also help maintain product quality.

Poor Surface Finish

A poor surface finish makes containers look rough, wrinkled, or uneven. This defect often results from process parameters that are not optimized:

- Improper extrusion temperature can cause brittleness or poor plasticization.

- Excessive inflation ratio may lead to instability and surface wrinkles.

- High traction ratio makes thickness control difficult, risking breakage and defects.

Technicians recognize poor surface finish by inspecting for orange peel patterns, vertical stripes, or rough areas. Solutions include cleaning the mold cavity, adjusting inflation pressure, and repairing the mold. Sandblasting the mold and increasing inflation pressure can also improve surface appearance.

Bubbles and Voids

Bubbles and voids appear as small pockets or holes within the molded part. Many plastic resins absorb humidity from the air. When exposed to heat during blow molding, moisture turns to steam and creates bubbles in the melt. These bubbles may become trapped in the finished product.

Operators can prevent bubbles and voids by:

- Thoroughly drying materials before processing.

- Increasing injection pressure and extending injection time.

- Lowering cylinder temperature for a more consistent melt.

- Reducing product thickness and adding reinforcement ribs.

- Ensuring mold vents are clear and correctly sized.

Technicians also clean the die mouth and mold cavity to eliminate black spots and vertical stripes. Increasing blowing air pressure can resolve wall bubbles, while repairing the mold and adjusting cooling temperature helps fix rough surfaces.

Top-Load Strength Defects

Top-Load Weakness

Top-load describes the vertical force that a blow molded container can withstand before it deforms or collapses. Top-load strength, sometimes called crush strength, measures the structural resistance of a bottle or container under a compressive load. This property ensures that bottles maintain their shape and integrity during filling, capping, and stacking.

| Aspect | Description |

|---|---|

| Definition | Top-load strength, also known as crush strength, evaluates a packaging material’s structural resistance under a compressive load. |

| Purpose | Ensures packaging integrity while minimizing material use, a process known as ‘downgauging’ or ‘light-weighting’. |

| Testing Method | A bottle is placed on a test stand, and a load is applied until deformation is detected, capturing the maximum force as top-load strength. |

Top-load strength plays a critical role in packaging. Manufacturers use this measurement to confirm that PET bottles meet performance standards. They also evaluate resistance during filling, capping, and stacking processes. If a container has insufficient top-load strength, it may collapse or leak during transport or storage.

Causes of Low Top-Load Strength

Several common causes can reduce top-load in blow molding. Wall thickness variation often creates weak points in the container. Parison sag leads to uneven distribution of material, especially at the bottom or sides. Improper processing, such as incorrect settings of ISBM machine, can also lower top-load.

Operators may notice that bottles with thin walls or uneven material distribution fail top-load tests. These defects often result from:

- Poor parison control, which causes inconsistent wall thickness.

- Incorrect temperature or pressure settings on the ISBM machine.

- Inadequate mold design, which fails to support uniform material flow.

- Short parison length, which does not fill the mold completely.

- High blow-up ratio, which stretches the material too thin.

Wall thickness variation and parison sag both weaken the structure of the bottle. When the material is not distributed evenly, the container cannot resist vertical loads. Improper cooling or rapid ejection from the mold can also introduce stress, further reducing top-load.

Note: Low top-load strength not only affects the safety of the product but also increases the risk of leaks and deformation during stacking.

Prevention in ISBM Machine

Manufacturers can improve top-load by following several best practices, especially when using ISBM machines. These steps help maintain quality and reduce the risk of defects:

- Material Selection: Choose materials with suitable mechanical properties and melt flow characteristics. Test different resins to find the best option for blow molding applications.

- Mold Design Optimization: Design molds to maintain uniform wall thickness and minimize defects. Use mold flow simulation software to identify and correct potential issues before production.

- Process Optimization: Control process parameters such as temperature, pressure, and cooling time. Regularly monitor and adjust these variables to prevent top-load defects.

- Quality Control Measures: Implement strict quality control protocols. Inspect and measure containers to detect defects early.

Operators can also adjust ISBM machine settings to improve top-load strength:

- Increase injection time to ensure the preform fills completely before switching to the holding stage.

- Raise mold temperature to reduce viscosity at the cavity wall, allowing better material flow.

- Increase gate temperature in hot runner molds for improved flow through the gate region.

- Elevate cylinder or barrel temperature to enhance melt flowability.

- Lower the switchover point (VP position) to prevent premature transition to packing.

- Increase back pressure to improve melt homogeneity and shot consistency.

Tip: Regular maintenance of ISBM machines and molds helps prevent unexpected changes in wall thickness and ensures consistent top-load performance.

By following these guidelines, manufacturers can reduce the causes of low top-load and produce containers that meet industry standards for strength and quality.

Moisture-Related Blow Molding Defects

Moisture Effects

Moisture in resin stands out as one of the most common problems in blow molding. When water remains in the resin, it can cause bubbles, voids, and surface defects in pet bottles. These problems often result in pearlescence and haze, making the bottles look cloudy or streaked. Moisture also leads to structural weaknesses, brittleness, and even bottle leaks. The presence of water can break down the polymer chains, causing degradation and reducing the mechanical properties of blow molding products. This breakdown often results in uneven wall thickness, non-uniform horizontal wall thickness, and uneven vertical wall thickness. These issues can cause volume reduction of blow molding products and make the quality of blow molding products fluctuate.

The table below summarizes the negative impacts of moisture in resin:

| Negative Impact | Description |

|---|---|

| Structural Weaknesses | Moisture can form bubbles that weaken the part. |

| Brittleness | Unremoved moisture weakens the resin’s molecular bonds, making parts fragile. |

| Surface Defects | Moisture trapped in resin can lead to splay streaks and other surface issues. |

| Degradation of Polymer | Hydrolysis breaks covalent bonds, reducing molecular weight and properties. |

| Dimensional Instability | Moisture affects viscosity and shrinkage, leading to improper fit or function. |

Moisture-related defects, such as bubbles and voids, can reduce the long-term durability of pet bottles. These problems often cause weak seams, difficulty in mold release, and even high scrap rate due to leaks or mold damage.

Prevention Methods

Manufacturers can prevent moisture-related problems by following several best practices. Proper drying of resin before processing is essential. Hygroscopic polymers, such as those used for pet bottles, require thorough drying to remove moisture inside the pellets. Non-hygroscopic polymers can still pick up surface moisture, especially in humid environments, so dehumidified air drying is recommended. Using low dew point air in the drying system helps remove humidity before heating the resin. Testing the initial moisture content of the resin is crucial, as storage conditions can affect moisture levels.

Key prevention steps include:

- Set drying conditions based on resin type.

- Use dehumidified air dryers for both hygroscopic and non-hygroscopic resins.

- Test moisture content before processing.

- Store resin in sealed containers to avoid moisture absorption.

- Regularly inspect drying equipment for proper function.

By following these steps, manufacturers can reduce common problems like uneven wall thickness, difficulty in mold release, and volume reduction of blow molding products. These methods also help prevent non-uniform horizontal wall thickness and ensure the quality of blow molding products does not fluctuate. Effective moisture control leads to improved product quality, enhanced processing efficiency, and fewer issues such as scrap, bottle wall thickness defects, and incorrect blow pressure.

Conclusion

Identifying blow molding defects plays a vital role in quality control and production efficiency. Regular inspections, real-time monitoring, and automated quality tools help catch issues early, reduce waste, and improve consistency. Understanding defect causes and prevention in ISBM machine operations leads to better training, effective material handling, and strong quality management. Plants that use systematic approaches, such as the DMAIC model, have reduced defects significantly. By applying these insights, manufacturers can boost top-load strength and deliver higher-quality products.

FAQ

What Causes Uneven Wall Thickness in Blow Molding?

Operators often see uneven wall thickness from poor parison control, incorrect temperature, or mold misalignment. They can improve results by adjusting machine settings and checking mold alignment.

How Can Manufacturers Prevent Flash Formation?

Regular mold maintenance and correct clamping pressure help prevent flash. Technicians should inspect molds for wear and set machines to the recommended parameters.

Why Do Bubbles Appear in Blow Molded Products?

Bubbles usually form when moisture remains in the resin. Drying the resin before processing removes water and reduces bubble formation.

What Is Top-Load Strength and Why Does It Matter?

Top-load strength measures how much vertical force a container can handle before collapsing. Strong top-load ensures bottles survive stacking and transport.

How Do ISBM Machine Settings Affect Product Quality?

| Setting | Effect on Quality |

|---|---|

| Temperature | Controls material flow |

| Pressure | Affects wall thickness |

| Cooling Time | Reduces stress and warping |

Proper settings lead to consistent, high-quality products.