Blog

- All

- IBM Machine

- ISBM Machine

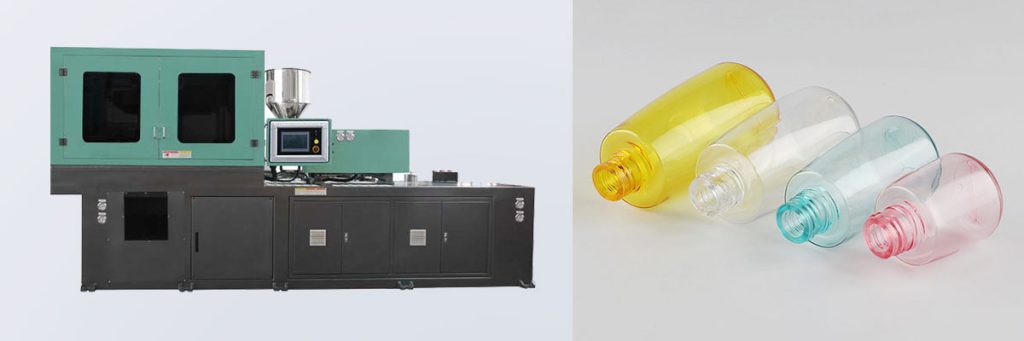

Top Operator Skills for Plastic Bottle Injection Molding Machine Success

By LydiaPosted on November 27, 2025Operators of plastic bottle injection molding machine need a strong set of skills to achieve high efficiency, quality, and safety.…

What Every Manufacturer Should Know About Plastic Preform Quality?

By LydiaPosted on November 20, 2025Manufacturers often ask what factors influence plastic preform quality. PET preform quality plays a vital role in protecting product integrity,…

How Do Blow Molding Machine Suppliers Help Create Custom Bottle Designs?

By LydiaPosted on November 12, 2025Blow molding machine suppliers play a vital role in turning creative bottle design ideas into real products that meet manufacturing…

Top Tips to Optimize Air Consumption in Stretch Blow Moulding Machines

By LydiaPosted on November 8, 2025Manufacturers achieve optimal air consumption by auditing compressed air systems, fine-tuning machine settings, upgrading to efficient equipment, and implementing air…

How Injection Stretch Blow Moulding Machine Improves Bottle Uniformity and Strength?

By LydiaPosted on November 5, 2025An injection stretch blow moulding machine shapes bottles with high precision, leading to consistent thickness and strong walls. Uniformity in…

How Injection Moulding Bottles Enhance Product Appearance and Strength?

By LydiaPosted on November 3, 2025Injection moulding bottles stand out for superior appearance and strength. The process delivers unmatched precision, smooth finishes, and lasting durability.…

Household and Cleaning Product Packaging with Advanced Blow Molding Applications

By LydiaPosted on November 1, 2025Blow molding applications drive major changes in household and cleaning product packaging. Manufacturers now achieve rapid production, leakproof containers, and…

How to Optimize Cooling Efficiency in Blow Molding System?

By LydiaPosted on October 30, 2025Operators can optimize cooling efficiency in a blow molding system by adjusting temperature, pressure, and flow rate with precision. The…

The Impact of Artificial Intelligence on Bottle Blow Molding Machine in 2025

By LydiaPosted on October 27, 2025Automation and AI continue to reshape the bottle blow molding machine. Manufacturers now see smarter automation, improved efficiency, and greater customization…

Improving Transparency in the Stretch Blow Moulding Process

By LydiaPosted on October 25, 2025Manufacturers improve transparency in the stretch blow moulding process by focusing on several critical factors. Material selection plays a key…

Why Stable Air Pressure Matters for PET Blow Moulding Machine Performance?

By LydiaPosted on October 23, 2025Stable air pressure plays a critical role in the performance of a PET blow moulding machine. Operators rely on a…

Key Stages in the PET Preforms Manufacturing Process

By LydiaPosted on October 21, 2025The PET preforms manufacturing process plays a vital role in meeting the global demand for lightweight and sustainable packaging. Impact AreaDescriptionProduct…