Blow molding machines shape the beverage industry by producing consistent, high-quality bottles at scale. Automation and Industry 4.0 technology now drive production, transforming raw materials into reliable beverage containers with remarkable speed and precision. The IBM machine and ISBM machine both play vital roles in modern packaging. The table below highlights how automation boosts efficiency, quality, and sustainability in beverage production:

| Benefit | Description |

|---|---|

| Enhanced Efficiency | Automation expedites production procedures, resulting in a greater yield. |

| Consistent Quality | Automated systems guarantee consistency in product quality. |

| Cost Savings | Automation can drastically lower operating and labour costs over time. |

| Reduced Waste | Improved process control leads to less material waste. |

Key Takeaways

- Blow molding machines enhance efficiency in beverage production by automating processes, leading to faster output and lower costs.

- Consistent quality is achieved through advanced technology, ensuring that every bottle meets strict safety and design standards.

- Material versatility allows manufacturers to produce bottles from various plastics, optimizing performance and reducing waste.

- Automation and Industry 4.0 technologies improve production accuracy, enabling real-time quality control and reducing errors.

- Sustainability is prioritized with the use of recycled materials and energy-efficient processes, supporting environmental goals in packaging.

Blow Molding Machines in Beverage Packaging

Role in Consistency and Quality

The beverage industry relies on the bottle injection molding machine to deliver beverage bottles that meet strict size and shape standards. Each bottle must fit perfectly with automated filling lines and sealing equipment. Blow molding machines transform raw materials, such as plastic resins, into finished bottles. The process begins with the injection of molten plastic into a mold. High-pressure air stretches and blows the plastic into the desired shape. Advanced technology and precision engineering ensure accuracy during stretching and blowing. Control systems allow precise adjustments of temperature, pressure, and timing to meet specific bottle specifications.

Consistency in bottle production is critical for both safety and brand reputation. Even small variations can cause leaks or failures during transport. The bottle molding machine uses servo stretch blowing and infrared heating to enhance bottle quality and reduce defects. These features minimize stress marks and uneven walls, resulting in reliable bottles for beverage packaging.

| Feature | Impact on Quality Consistency |

|---|---|

| Precision Engineering | Ensures high-quality bottles with consistent dimensions |

| Servo Stretch Blowing | Enhances bottle quality, reducing defects |

| Infrared Heating | Minimizes stress marks and uneven walls |

Quality control measures play a vital role in preventing defects in bottles. The bottle molding machine follows a series of steps to maintain high standards:

- Material selection ensures the right properties for each bottle.

- Mold design optimization creates uniform bottles and reduces defects.

- Process optimization controls temperature and pressure for quality.

- Strict quality control protocols detect defects early in production.

The packaging industry depends on these measures to deliver safe and attractive bottles for beverages.

Material Versatility

Material versatility sets the bottle molding machine apart in the packaging industry. Manufacturers use a range of materials to produce bottles for different beverage types. Common materials include:

- Polyethylene Terephthalate (PET)

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

Polyethylene Terephthalate (PET) stands out in the beverage industry. PET offers reliability, durability, and flexibility, making it ideal for manufacturing bottles. The bottle blowing machine can handle these materials efficiently, supporting the production of both plastic bottles and other blow molded products.

Material versatility also improves packaging reliability. Specialized barrier layers protect beverages from oxygen, moisture, and UV rays. This protection helps maintain product quality and freshness. By combining different materials, manufacturers optimize material usage and reduce costs while ensuring strong performance. Multi-layer designs enhance mechanical properties, resulting in stronger bottles that withstand transportation and handling.

The bottle molding machine supports the production of millions of bottles each year. Its ability to work with various materials ensures that the packaging industry can meet the demands of beverage production. Reliable bottles keep beverages safe from contamination and preserve taste, supporting the growth of the beverage industry.

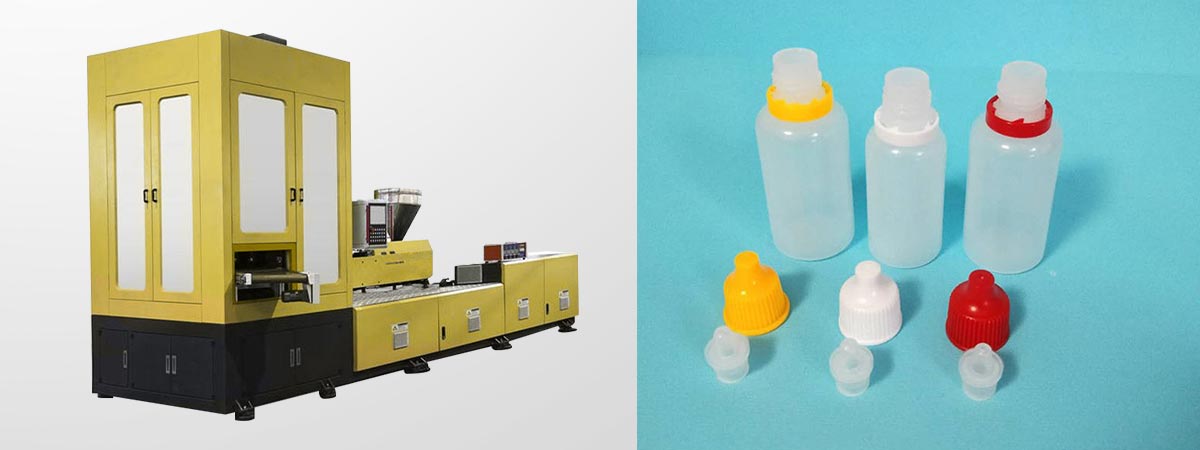

Types of Bottle Molding Machine

Modern bottle production relies on several types of bottle molding machines. Each machine uses a different method to create bottles and hollow plastic parts for the beverage industry. The main types include extrusion blow molding machines, ISBM machines, and IBM machines. The table below compares common methods and their features:

| Type of Machine | Method | Advantages | Disadvantages |

|---|---|---|---|

| One-step method | Nissei, SIPA | Energy-saving, no need for cooling or reheating | Slower speed, max 24,000 BPH |

| Two-step method | Linear, Rotary | Higher production capacity (1,500-2,400 BPH) | Efficiency drops with larger molds |

| Linear type | Festa, Chumpower | Separate blowing valve group for each cavity | |

| Rotary type | Festa, Tech-long, Sidel, Krones | High speed and efficiency for large volumes |

Extrusion Blow Molding Machine

The extrusion blow molding machine creates bottles and hollow plastic parts by melting plastic and forming a tube called a parison. The process follows these steps:

- The machine heats and melts plastic evenly.

- It forms a hollow tube and places it in a cooled metal mold.

- Compressed air inflates the tube into the shape of a bottle.

- The plastic cools and keeps its shape.

- Sensors monitor quality in real time.

Quality control sensors help ensure every bottle meets strict standards. If the machine detects any problem, it can adjust or stop production. This process produces bottles and hollow plastic parts for many beverage applications.

ISBM Machine

The ISBM machine, or Injection Stretch Blow Molding machine, stands out for making high-quality bottles. It uses a two-step or one-step process to create strong, lightweight, and transparent bottles. ISBM bottles have excellent barrier properties and uniform wall thickness. The ISBM machine produces leak-resistant bottles that work well for mass distribution. The one-step ISBM suits custom shapes and small batches, while the two-step ISBM fits large-scale production.

- ISBM machines improve mechanical strength and reduce material use.

- They create high-quality bottles that protect beverages and keep them fresh.

- Many beverage companies choose ISBM machines with reliable ISBM molding.

IBM Machine

IBM machine, or Injection Blow Molding machine, specializes in small-to-medium-sized bottles and hollow plastic parts. The machine often serves the cosmetic and pharmaceutical industries, but they also make bottles for beverages. IBM machine produces bottles with complex shapes and high precision. The table below shows how IBM and ISBM machines differ:

| Technology | Applications | Advantages |

|---|---|---|

| IBM | Cosmetics, pharmaceuticals, small containers | High-precision, complex shapes, small-to-medium sizes |

| ISBM | Beverage bottles, food packaging | Larger, stronger, more durable bottles |

IBM machines help manufacturers create hollow plastic parts that require detailed shapes and tight tolerances. Beverage companies use IBM machines for specialty bottles and unique packaging designs.

Blow Molding Process

Heating and Shaping

The blow molding process begins with the preparation of raw plastic. Workers blend the material with colors and additives to achieve the desired properties. The plastic then moves into the extrusion stage, where machines heat it until it becomes molten. This molten plastic forms a parison, a hollow tube that will become the final bottle. The parison enters a mold, where high-pressure air inflates it to match the mold’s shape. The bottle blowing process relies on precise temperature control and advanced technology to ensure quality.

| Factor | Description |

|---|---|

| Mold Temperature | Controlled at 120℃~145℃ to eliminate internal stress and improve crystallinity for high-temperature resistance. |

| Heating Method | Utilizes far infrared radiation and heat circulation for uniform heating of the bottle preform. |

| Cooling Process | High-pressure cooling air shapes the bottle wall after blowing, ensuring structural integrity. |

Proper heating and shaping guarantee that bottles have strong walls and consistent quality. The cooling process locks the shape and prevents defects, making the blow molding process reliable for beverage packaging.

Automation and Industry 4.0

Automation plays a key role in the blow molding process. Custom conveyors transport preforms to the heating machine, ensuring safe and efficient movement. Automated systems align and move preforms into the blow molding machines, reducing manual errors. During the bottle blowing process, conveyors also help with cooling and transfer bottles to the next stage.

Industry 4.0 technology has transformed production. AI-powered quality inspection systems detect micro-cracks and dimensional inconsistencies. Vision inspection systems identify defects in real time, while automated leak testers check container integrity. Real-time insights allow operators to adjust settings quickly, improving consistency and reducing errors. Augmented reality (AR) helps operators visualize equipment operations and monitor sanitation levels, which lowers contamination risks.

Quality Control

Quality control remains essential throughout the blow molding process. Modern technology uses wall thickness analysis to ensure bottles have uniform walls. Sensors measure multiple points on each bottle, checking for proper material distribution. The bottle blowing process also includes defect detection, which identifies air pockets, cracks, or flaws. High-speed imaging systems measure container dimensions and reject bottles with sealing issues. Automatic corrections adjust machine settings based on real-time data, maintaining high quality in every production run.

Consistent quality control ensures that every bottle meets strict industry standards, supporting safe and reliable beverage packaging.

Benefits for Bottle Production

Efficiency

Blow molding machines have transformed production in the beverage industry. These machines operate at high speeds, increasing the output of bottles and supporting high production efficiency. Automated systems minimize downtime and reduce labor costs, allowing manufacturers to produce high-quality bottles with fewer resources. The versatility of these machines enables the creation of various bottle designs, meeting the diverse needs of beverage packaging. Companies benefit from reduced material waste, which lowers production costs and improves overall quality. A North American beverage company improved bottle production by switching to a more efficient molding process, producing bottles faster with less waste and consistent quality.

- Blow molding machines deliver high-quality bottles with precision, reducing defects.

- Automated processes in bottle blowing machine technology enhance production speed and consistency.

- Reduced material waste leads to significant cost savings for manufacturers.

Scalability

Scalability remains essential for the packaging industry, especially when meeting the demands of mass beverage production. Blow molding machines allow manufacturers to quickly adjust production volumes and bottle sizes. Recent advancements in automation and digital control systems have increased operational efficiency, enabling rapid changeovers and higher production speeds. The market for plastic bottle molding machine continues to grow due to rising global demand for lightweight, durable, and cost-effective packaging solutions. The table below highlights the impact of blow molding machines on scalability:

| Evidence | Description |

|---|---|

| Global Demand | Over 61% of the packaging industry relies on blow-molded solutions. |

| Sector Contribution | 46% of blow-molded product demand comes from beverage, food, and pharma. |

| Sustainability Impact | Machine usage has increased by 29% in sustainability-focused projects. |

Sustainability

Sustainability has become a priority in beverage packaging. Blow molding machines support environmental sustainability by enabling the use of recycled materials and energy-efficient processes. Innovations such as Sidel’s 1SKIN bottle, made from 100% recycled PET, show how technology can improve recyclability and reduce material usage. Manufacturers now use biodegradable polymers and bio-based plastics, which help decrease reliance on fossil fuels and reduce waste. Energy-efficient machines lower energy consumption, aligning with global carbon reduction efforts. These practices ensure that high-quality bottles meet both consumer expectations and environmental standards.

- Energy-efficient blow molding machines reduce energy use during production.

- Biodegradable and bio-based plastics support sustainable packaging.

- Technology advancements help manufacturers achieve long-term cost savings and environmental sustainability.

Conclusion

Blow molding machines drive the beverage industry by enabling efficient production of high-quality bottles for modern packaging. Their technology supports rapid production, design flexibility, and sustainability.

- Manufacturers achieve high output and consistent quality, meeting strict standards for beverage packaging.

- Machines produce bottles in various shapes and sizes, using lightweight, recyclable materials.Advanced technology continues to shape production, allowing stakeholders to customize equipment and optimize quality. The future promises greater innovation, eco-friendly solutions, and enhanced production capabilities.

FAQ

What Types of Materials Do Blow Molding Machines Use in Production?

Blow molding machines use materials like PET, HDPE, and PP. These plastics support safe and efficient production. Each material offers unique properties for strength, clarity, or flexibility. The beverage industry selects materials based on the needs of each bottle.

How Does Automation Improve Production Efficiency?

Automation increases production speed and reduces errors. Machines handle repetitive tasks, which lowers labor costs. Automated systems also monitor quality in real time. This approach ensures consistent results and helps the beverage industry meet high demand.

Why Is Quality Control Important in Bottle Production?

Quality control checks every stage of production. Sensors and cameras detect defects early. This process prevents leaks or weak spots in each bottle. Reliable quality control protects consumers and supports the reputation of the beverage industry.

Can Blow Molding Machines Support Sustainable Production?

Yes, modern machines use recycled plastics and energy-saving technology. These features reduce waste and lower energy use during production. Sustainable practices help companies meet environmental goals and support long-term success in the beverage industry.

What Are the Main Steps in the Bottle Production Process?

The process starts with melting plastic, forming a parison, and shaping it inside a mold. Machines then cool and release the finished bottle. Each step uses precise controls to ensure high-quality production and meet the needs of the beverage industry.