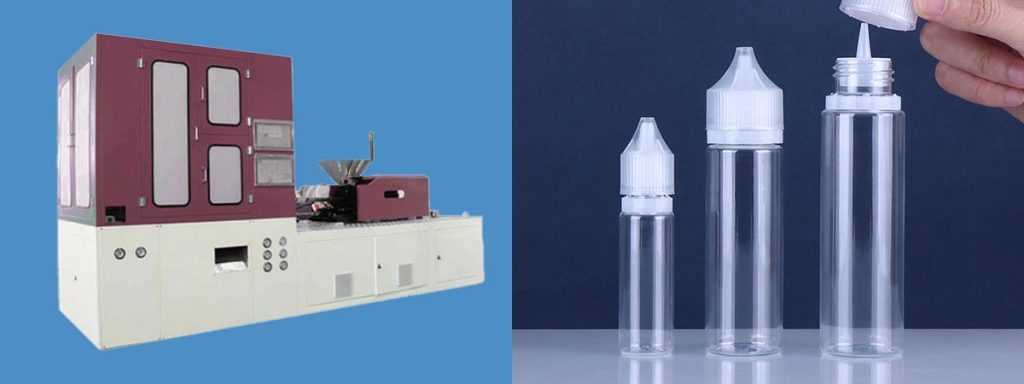

Stretch blow molding machines in 2025 showcase rapid innovation, driven by technology and shifting industry trends. Automation, digitalization, and sustainability lead the transformation, with ISBM machine and IBM machine integrating AI, IoT, and predictive maintenance.

The industry’s global market growth is evident:

Metric Value Market Value (2022) USD 939.81 million Projected Market Value (2030) USD 1,266.54 million Compound Annual Growth Rate 3.80%

Manufacturers now prioritize energy efficiency, new materials, and customization. Asia-Pacific’s growth, strong regulatory support, and demand for sustainable packaging drive these trends, while technology enables flexible, high-performance solutions.

Key Takeaways

- Automation and robotics in stretch blow molding machines boost production speed, precision, and reduce labor costs.

- Energy-efficient designs and use of recycled or bioplastic materials lower costs and support sustainability goals.

- IoT, AI, and smart controls enable real-time monitoring, predictive maintenance, and improve product quality.

- Modular machine designs and rapid changeovers allow flexible, customized packaging with minimal downtime.

- Advanced technologies like 3D printing and digital controls help create complex bottle shapes and speed up development.

Automation Trends

Robotics Integration

Robotics integration stands at the forefront of automation trends in stretch blow molding machine development. Manufacturers now deploy advanced robotics to streamline bottle handling, mold changes, and packaging. ISBM machine and IBM machine benefit from six-axis robots, servo-driven shuttles, and automated removal systems. These advancements in ISBM molding deliver faster cycle times, higher precision, and reduced labor requirements.

The following table highlights recent robotics integration in leading ISBM and IBM machine systems:

| Manufacturer / Supplier | Machine / System | Robotics Integration / Automation Features | Key Benefits / Notes |

|---|---|---|---|

| Engel Machinery, Inc. | IBM system with e-motion 220 T | Engel easix six-axis robot for bottle removal at the fourth station | Proof-of-concept for Alpla; cycle time 7-8 sec; potential expansion to 96 cavities |

| Nissei ASB Company | ASB-12M/IBM (ISBM variant) | Vertical clamp, servo-driven shuttle, neck orientation with integrated register | Deep pinch-style handles; improved alignment; high output rates |

| Mould & Matic Solutions | Blowliner ISBM system | Servo control for stretch-blowing profiling; servoelectric stretching; internal clamping with aluminum grippers | Flexible preform rows; multi-layer containers; oval necks |

These robotics-driven advancements in blow-molding technology support greater production efficiency and flexibility.

AI And Smart Controls

AI and smart controls transform stretch blow molding machines by enabling real-time monitoring, adaptive process adjustments, and predictive analytics. Advanced blow molding machines now feature integrated sensors and AI-driven systems that optimize injection, clamping, and lubrication.

Key AI features include:

- Real-time power management for energy optimization.

- Adaptive control of injection fill and hold phases, reducing part weight variation.

- Closed-loop clamp force control for precise operation and energy savings.

- Rapid fault detection and troubleshooting, minimizing downtime.

Industry advancements in blow molding technology, such as HT ENERGY and HT DIAGNOSE, ensure consistent product quality and improved efficiency. ISBM machine and IBM machine equipped with these smart controls achieve higher production efficiency and reduced operational costs.

Predictive Maintenance

Predictive maintenance represents a major leap in advanced blow molding equipment. Stretch blow molding machine operators now rely on sensors and data analytics to anticipate equipment failures before they occur.

- Predictive maintenance technologies enable proactive scheduling, reducing unexpected downtime.

- Real-time monitoring and remote access allow continuous performance tracking and swift troubleshooting.

- Centralized monitoring systems identify trends and potential issues early, ensuring reliable operations.

- Automated quality control systems, such as vision inspection, detect defects in real time, preventing malfunctions.

These advancements in blow-molding machines extend machinery lifespan, improve return on investment, and support the ongoing evolution of blow-molding technology. Machine automation, combined with predictive maintenance, drives efficiency and reliability in modern production environments.

Energy Efficiency

Eco-Friendly Designs

ISBM machine and IBM machine have prioritized eco-friendly designs to address the growing demand for sustainability in plastic bottle production. Recent advancements include optimized heating systems and improved air recovery solutions, which significantly reduce energy consumption during bottle manufacturing. These innovations lower both manufacturing costs and the carbon footprint of the process.

Key eco-friendly features include:

- Use of recycled materials such as rPET and rPP, which reduces reliance on virgin plastics and lowers greenhouse gas emissions.

- Multi-layer co-extrusion technology that integrates recycled content while maintaining product quality.

- Energy-efficient machine designs, including fully electric or hybrid servo motors, that contribute to a reduced carbon footprint.

- Advanced automation and control systems that optimize production processes, minimizing waste and energy use.

- Recycling of production waste like trim and flash, supporting circular economy principles.

These features help companies meet environmental regulations and enhance their sustainability goals, making eco-friendly packaging a practical reality.

Reduced Operational Costs

Energy-efficient blow molding equipment directly impacts operational costs in plastic bottle production. Newer ISBM machine and IBM machine use less energy, which supports both efficiency and sustainability. These machines often require less maintenance and have longer lifespans, leading to further cost savings. Integration of AI and IoT technologies enables predictive maintenance and real-time monitoring, which minimizes downtime and optimizes production efficiency.

A comparison shows that traditional machines consume 25% more energy than newer hybrid models. Electricity accounts for about 20% of total production costs, so energy savings are crucial. New energy-efficient machines reduce power use by 15% to 30%, directly lowering expenses and supporting efficient packaging machinery.

Lightweight Solutions

Lightweight solutions in stretch blow molding have transformed plastic bottle production. ISBM machine enable precise control over material distribution, allowing the creation of containers with thinner walls and reduced material consumption. This approach lowers production costs while maintaining or even enhancing mechanical properties such as strength and barrier performance.

Lightweight, shatter-resistant containers improve handling and safety during transportation across various packaging sectors, including food, pharmaceuticals, and household products. The technology supports ergonomic and aesthetic designs, making eco-friendly packaging more attractive and practical. By reducing material usage, manufacturers achieve greater efficiency and support sustainability in every stage of production.

Technological Innovations

IoT and Connectivity

IoT and connectivity have become central to the evolution of stretch blow molding machine performance. ISBM machine and IBM machine now feature IoT sensors that monitor critical production parameters such as temperature, pressure, and cycle times. These sensors collect real-time data, eliminating manual entry errors and providing accurate information for analysis. Operators use dashboards and real-time alerts to make immediate adjustments, which reduces defects and downtime. Advanced algorithms and machine learning analyze sensor data to detect anomalies, optimize machine settings, and predict maintenance needs. Predictive maintenance based on IoT data extends machine lifespan and minimizes unexpected failures.

Engineers can remotely access dashboards to monitor machine status and respond quickly to issues. IoT-driven predictive maintenance uses sensor data and AI to forecast component failures, minimizing unexpected downtime. Real-time quality control through sensor data analysis reduces defects and material waste by allowing immediate adjustments. Integration with automation and robotics improves workflow efficiency and cycle times. Digital twins simulate production environments in real time, enabling process optimization without halting actual production. These cutting-edge technologies support regulatory compliance by ensuring traceability and accurate production records. Data-driven insights allow optimization of production schedules, energy use, and overall process efficiency, leading to higher product quality. The integration of IoT in blow molding technology marks a significant step forward in industry advancements.

3D Printing in Blow Molding

3D printing has transformed the customization and prototyping of stretch blow molding machine components. Manufacturers now use 3D printing to create functional prototypes of molds and parts using materials like PolyJet and FDM. This technology supports low to moderate production levels and allows multiple design iterations, making it ideal for prototyping and customization. 3D printed tools can withstand hundreds of cycles and maintain stability under heat, enhancing operational efficiency. The technology facilitates rapid design changes and supports complex geometries that traditional manufacturing struggles to achieve.

3D printing accelerates product development by enabling rapid prototyping and testing of designs before mass production. It allows production of highly customized plastic parts tailored to specific design requirements, which traditional methods find challenging. The technology is cost-effective for low-volume production runs by eliminating the need for expensive molds. Complex geometries can be produced that are difficult or impossible with conventional manufacturing. Ongoing innovations in materials and printing techniques continue to enhance 3D printing’s role in plastic mold making and part production. Alongside AI and machine learning, 3D printing stands as a key emerging technology that supports the evolving needs of blow molding technology. These advancements enable manufacturers to deliver innovative solutions and meet the demands of a rapidly changing market.

Digital Controls

Digital controls have redefined the precision and flexibility of stretch blow molding machines. They now feature advanced control systems with automation and digital connectivity. Operators can monitor and adjust key parameters such as temperature, pressure, and cycle times in real time. This results in consistent, high-quality production and greater flexibility in handling different container designs. Digital control systems and AI-driven process optimization enhance consistency and sustainability in stretch blow molding. Real-time monitoring of process parameters ensures precision with minimal manual intervention.

Automation and broader material options support customization and adaptability to various packaging needs. For example, KHS has enhanced its Innocheck TSI closure inspector with AI capabilities for tethered caps on PET bottles, demonstrating how AI integration improves inspection precision and process flexibility. TECH-LONG integrates advanced control systems with automation and digital connectivity, allowing real-time monitoring and easy adjustment of key parameters. This results in consistent, high-quality production and greater flexibility in handling different container designs. Digital transformation accelerates product development and enhances manufacturing precision through a digital-first approach. Immersive design using VR and 3D CAD tools allows designers to interact with 3D models dynamically, speeding ideation and improving design quality.

Predictive simulation enables virtual testing and optimization, reducing physical prototyping time and material waste. Rapid functional prototyping with advanced 3D printing drastically shortens development timelines by producing realistic prototypes within days. These innovations collectively reduce development time, improve material efficiency, and boost sustainability in packaging production. KHS developed Unit Mold Control, a digital system that automates and optimizes individual mold stations in stretch blow molding machines. The system precisely regulates material distribution per station, reducing wall thickness variation and improving bottle quality and stability, especially with high recycled PET content. Data collected supports condition-based maintenance, enhancing operational efficiency and reducing downtime. This digital control exemplifies how digital transformation directly supports innovative manufacturing processes in blow molding technology.

Note: The adoption of cutting-edge technologies such as IoT, 3D printing, and digital controls presents challenges. Manufacturers must address material variability, complex product designs, and the need for advanced quality control. However, these technological innovations drive industry advancements, enabling innovative solutions and supporting the ongoing evolution of blow molding technology.

Materials and Sustainability

Bioplastics Adoption

Stretch blow molding machines have accelerated the adoption of bioplastics in injection stretch blow molding process. Companies now use bio-based polymers such as PLA and bio-PET to produce bottles and containers that support sustainable packaging. Bioplastics offer reduced reliance on fossil resources and lower greenhouse gas emissions. Manufacturers select these materials for food, beverage, and personal care packaging solutions. The industry recognizes bioplastics as a key driver for sustainability, especially as regulatory bodies encourage sustainable practices. Production lines equipped with advanced controls ensure consistent quality and compatibility with bioplastics, making them viable for high-volume applications.

Bioplastics provide a renewable alternative to traditional plastics. Their use in ISBM machine demonstrates a commitment to sustainability and innovation in packaging.

Recyclable Materials

Recyclable materials have become central to sustainable packaging strategies in stretch blow molding. CHUMPOWER’s Single Stage Stretch Blow Molder SS10-rPET integrates recycled PET (rPET) directly into the process, improving energy efficiency and reducing carbon emissions. The machine’s hybrid hydraulic system and optimized clamping mechanism minimize energy waste. By transferring preforms directly to the blowing section, manufacturers avoid reheating and lower operational costs. The plasticizing screw design reduces drying energy, supporting sustainability goals. These advancements enable the production of high-quality bottles with rPET content, meeting mandates such as Taiwan’s requirement for 25% rPET in packaging.

Manufacturers also design packaging with mono-material structures to simplify recycling and reduce contamination. Incorporating post-consumer recycled plastics decreases demand for virgin materials. Advanced ISBM machine and IBM machine platforms optimize cycle times and use heat recovery systems to further enhance sustainability. Lightweight packaging designs reduce material use and energy consumption during production and transport. Lifecycle assessments guide material choices, helping companies improve environmental performance and deliver sustainable packaging solutions.

Multi-Layer Structures

Multi-layer structures in stretch blow molded products offer enhanced functionality for packaging solutions. Stretch blow molding machines create containers with multiple layers, each serving a specific purpose. The outer layer provides environmental resistance, while the inner layer ensures food safety and purity. Barrier layers, such as EVOH or nylon, block gases and moisture, extending shelf life for sensitive products.

| Aspect | Benefits | Challenges |

|---|---|---|

| Layer Functions | – Outer layer: environmental resistance and stability | – Diverse materials complicate recycling |

| – Inner layer: food safety and content purity | – Adhesives and compatibilizers hinder material separation | |

| – Barrier layers: block gases and moisture, extend shelf life | ||

| Manufacturing | – Cooling techniques preserve layered structure, maintain uniformity | – Precise control needed in cooling and layer formation |

| Industry Applications | – Widely used in food & beverage, personal care, pharmaceutical packaging | |

| Recycling | N/A | – Recycling complexity and cost due to multi-material layers |

Manufacturers face challenges with recycling multi-layer packaging due to material separation issues. Despite these obstacles, multi-layer structures remain popular for applications requiring extended shelf life and product protection. The industry continues to innovate, seeking solutions that balance performance with sustainability.

Customization in Stretch Blow Molding Machines

Modular Machine Design

Manufacturers in 2025 rely on modular machine design to achieve flexibility and efficiency in stretch blow molding machines. The APF-Max series by PET Technologies demonstrates this trend with a modular concept that divides the machine structure into two parts. This design simplifies transport and installation for machines. Operators benefit from user-friendly controllers and compact dimensions, which support high output rates ranging from 3,000 to 14,000 bottles per hour.

- Modular systems incorporate double air recovery for both low and high pressure demands during pre-blow.

- Advanced NIR heating systems with ceramic reflectors ensure uniform preform heating and reduced energy consumption.

- Branded components and servo control systems enhance operator safety and flexibility.

- The modular approach enables quick mold changes and easier maintenance, aligning with modern production needs.

Modular machine design supports economic operation and adaptability, allowing manufacturers to respond rapidly to changing market demands.

Rapid Changeovers

Rapid changeover capabilities in stretch blow molding machines have transformed plastic bottle production. Innovations such as ergonomic mandrel heads and simplified neck changeover procedures reduce downtime from hours to minutes. Operators can switch between bottle neck sizes and product types efficiently, supporting smaller batch sizes and customized packaging.

A universal stretch blow molder now completes format changeovers, including restart time, in just 20–30 minutes. This improvement allows flexible production runs with batch sizes as small as 10,000 bottles. Manufacturers achieve higher efficiency, minimize downtime, and improve operator productivity.

Rapid changeovers enable manufacturers to meet the growing demand for customized designs in food, beverage, pharmaceutical, and personal care industries.

Complex Geometries

Technological advancements empower stretch blow molding machine platforms to produce complex geometries in plastic bottle production. 3D printing enables intricate mold designs with high precision and minimal waste. High-temperature resistant materials, such as advanced alloys and ceramics, maintain mold integrity under extreme conditions.

Digital twin technology allows virtual simulation and optimization of mold designs before production, reducing errors and improving complexity. Artificial Intelligence automates mold design tasks and optimizes parameters for better performance. Multi-material molding technologies combine different materials in a single mold, expanding design possibilities.

| Technology | Impact on Complex Geometries |

|---|---|

| 3D Printing | Enables intricate mold designs |

| Digital Twin | Simulates and optimizes mold designs |

| AI Automation | Automates and customizes mold parameters |

| Multi-Material Molding | Expands design possibilities |

Two-stage blow molding machine provides flexibility, high-speed production, and consistent quality, making it possible to manufacture bottles with unique shapes and features. Manufacturers deliver innovative solutions that meet evolving market requirements for efficiency, versatility, and eco-friendly packaging.

Customization in stretch blow molding machines reflects a commitment to innovative solutions, machine versatility, and sustainability improvements.

Innovative Blow Molding

Competitive Advantages

Manufacturers in 2025 gain significant benefits by adopting innovative blow molding. Machines now feature advanced automation and robotics, which streamline operations and reduce manual intervention. These advancements in blow molding technology improve precision and increase productivity. Companies also use sustainable materials, such as recycled and bio-based plastics, to reduce environmental impact and comply with regulations.

Key competitive advantages include:

- Automation and robotics integration for higher efficiency and less waste.

- Energy-efficient machines with variable speed drives and improved insulation, lowering operational costs.

- Modular machine designs with multi-layer capabilities and in-mold labeling, offering greater flexibility.

- Advanced control systems with real-time monitoring and predictive maintenance, reducing downtime.

- Industry 4.0 integration, including IoT and AI-driven analytics, for smarter manufacturing.

- Customization and flexibility for quick changeovers and varied production runs.

- Integration with 3D printing for complex designs and rapid prototyping.

- Use of high-performance and biodegradable polymers for improved product strength and sustainability.

Leading companies like Bekum, Nissei ASB, and Full Shine leverage these advancements to differentiate their products. They use smart sensors, AI-based controls, and hybrid hydraulic-electric machines to improve energy efficiency and product quality. These strategies help companies respond quickly to market changes and maintain strong growth.

Future Outlook

The future of innovative blow molding shows strong growth and rapid advancements. Global demand for packaged beverages and consumer goods continues to rise, driving the need for efficient ISBM machine and IBM machine. PET remains popular due to its lightweight and recyclable properties. Manufacturers focus on sustainable packaging and circular economy principles.

Emerging trends include:

- Compact and modular machine designs for flexible production.

- Energy-efficient machinery to reduce costs and environmental impact.

- Expansion into pharmaceuticals and cosmetics, beyond traditional beverage packaging.

- Digital integration with IoT and AI for lights-out manufacturing and predictive analytics.

- Machines capable of handling higher recycled PET content.

- Intelligent systems with self-optimization and lower maintenance needs.

Regional growth patterns show Asia-Pacific as a primary engine, while North America and Europe emphasize automation, sustainability, and regulatory compliance. Companies that invest in innovative blow molding technology will secure a competitive edge, adapt to evolving market demands, and achieve long-term growth.

Conclusion

Stretch blow molding machines in 2025 deliver material savings, high production efficiency, and enhanced recyclability. Manufacturers benefit from rapid growth, lower carbon footprints, and flexible packaging design. Stretch blow molding machines drive innovation, with ISBM leading in complex, high-performance packaging and IBM supporting cost-effective solutions. Experts recommend investing in automation, IoT, and flexible machines to capture new growth opportunities. Ongoing innovation ensures that stretch blow molding machine technology adapts to evolving market demands and secures future growth.

FAQ

What Are the Main Differences Between ISBM Machine and IBM Machine?

ISBM machine (Injection Stretch Blow Molding Machine) creates bottles with superior clarity and strength, ideal for PET packaging. IBM machine (Injection Blow Molding Machine) suits smaller containers and complex shapes. ISBM machine offers higher production speed, while IBM machine provides cost-effective solutions for specific applications.

How Does Automation Improve Stretch Blow Molding Efficiency?

Automation in ISBM machine and IBM machine increases production speed and accuracy. Robotics handle repetitive tasks, reducing errors and labor costs. Smart controls optimize processes in real time. Manufacturers benefit from fewer stoppages and consistent product quality.

Why Is Energy Efficiency Important In Modern Blow Molding Machines?

Energy efficiency lowers operational costs and reduces environmental impact. ISBM machine and IBM machine designs with advanced heating and air recovery systems use less power. Companies meet sustainability goals and comply with regulations by choosing energy-efficient equipment.

Can ISBM Machine and IBM Machine Use Recycled Or Bioplastic Materials?

Yes. ISBM machine and IBM machine process recycled PET (rPET) and bioplastics like PLA. These materials support sustainable packaging. Advanced controls ensure consistent quality, even with material variability.

What Customization Options Exist for Stretch Blow Molding Machines?

Manufacturers can select modular designs, rapid changeover features, and support for complex geometries. Stretch blow molding machines offer flexibility for different bottle shapes, sizes, and materials. Customization helps companies respond quickly to market trends and customer needs.